What is Eddy Current Testing?

Eddy current array (ECA) is a nondestructive testing technology that provides the ability to electronically drive multiple eddy current coils,which are placed side by side in the same probe assembly.Each individual eddy current coil in the probe produces a signal relative to the phase and amplitude of the structure below it.This data is referenced to an encoded position and time and represented graphically as a C-scan image.Most conventional eddy current flaw detection techniques can be reproduced with ECA inspections;however,the remarkable advantages of ECA technology allow improved inspection capabilities and significant time savings.

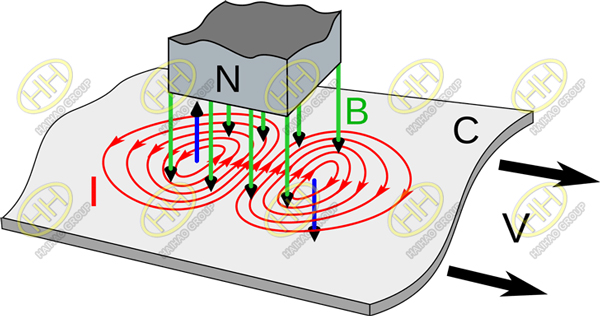

Schematic diagram of eddy current test

ECA technology includes the following advantages:

- A larger area can be scanned in a single-probe pass, while maintaining a high resolution.

- Less need for complex robotics to move the probe; a simple manual scan is often enough.

- C-scan imaging improves flaw detection and sizing.

- Complex shapes can be inspected using probes customized to the profile of the part being inspected.

Eddy current (EC) testing is a no contact method for the inspection of metallic parts. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is passed through one or more coils in a probe assembly. When the probe is linked with the part under inspection, the alternating magnetic field induces eddy currents in the test part. Discontinuities or property variations in the test part change the flow of the eddy current and are detected by the probe in order to make material thickness measurements or to detect defects such as cracks and corrosion.

Eddy Current Testing Of Flange

Over the years, probe technology and data processing have advanced to the point where eddy current testing is recognized as being fast, simple, and accurate. The technology is now widely used in the aerospace, automotive, petrochemical, and power generation industries for the detection of surface or near-surface defects in materials such as aluminum, stainless steel, copper, titanium, brass, and even carbon steel (surface defects only).

Eddy Current Testing

PIPE INSPECTION OF HEAT EXCHANGERS

Various materials could be checked, like carbon steel, stainless steel, duplex, alloy or other conductive materials.

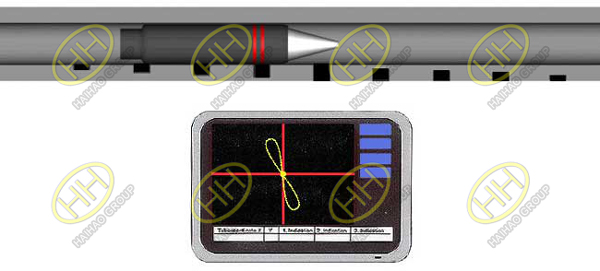

The drawing below represents schematically the defect detection by eddy current. The two coils (red) were pulled over the defect and the typical signal appeared on the screen. The inner and outer defects have different signals depending on their deepness. This gives the operator the opportunity to decide what kind of defect is in the tube.

Eddy current testing is always a comparative measurement, therefore EC-Works need:

- Inspection task based calibration pieces

• Inspection task designed probes

AND VERY IMPORTANT:

• Eddy Current is not a leak-test system

SURFACE CRACK INSPECTION

The cracks below could be found by eddy current. Special probes allow to detect inside cracks from outside, depending on the material and wall thickness. Even microcracks in Formula 1 Valves are detected with eddy current by EC-Works.

Benefits of Eddy Current Testing

Benefits of Eddy Current Testing

Eddy current offers the following capabilities:

Quick, simple, and reliable inspection technique to detect surface and near-surface defects in conductive material Can be used to measure material electrical conductivity Measurement of nonconductive coating Hole inspection with the use of high-speed rotating scanner and surface probe

Benefits of Eddy Current Array Testing

Compared to single-channel eddy current technology, eddy current array technology provides the following benefits: Drastically reduces inspection time. Covers a large area in one single pass. Reduces the complexity of mechanical and robotic scanning systems. Provides real-time cartography of the inspected region, facilitating data interpretation. Is well suited for complex part geometries. Improves reliability and probability of detection (POD).

If you would love to know more technical information,please feel free to contact us.Email:sales@haihaogroup.com