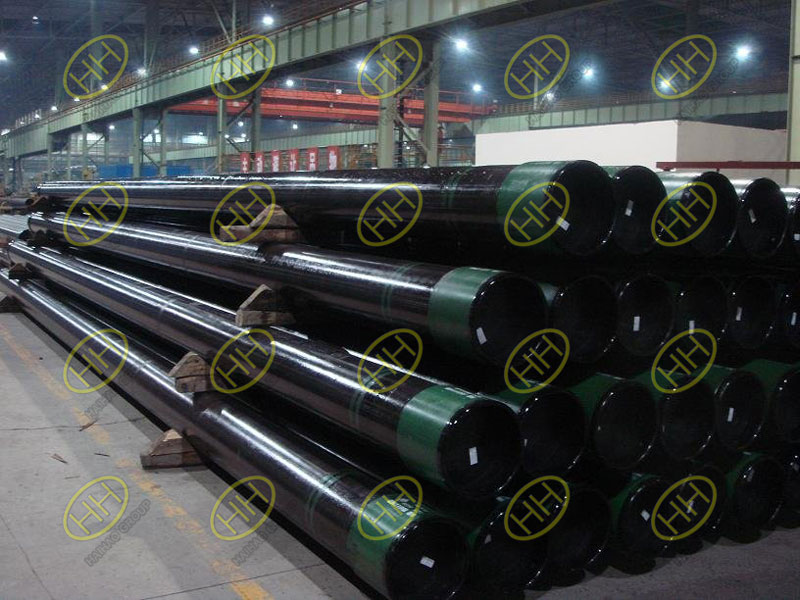

API 5CT steel casing and tubing pipes

API 5CT is standard technical specifications for steel casing and tubing pipes used for oil wells in petroleum and natural gas industries.API 5CT steel casing and tubing pipes are mainly used for drilling oil,gas and water wells and conveying oil,gas and water.

Specification of API 5CT steel casing and tubing pipes

Manufacture types: seamless steel casing and tubing pipes,welded steel casing and tubing pipes

API 5CT steel casing and tubing pipe size:

seamless steel casing and tubing pipes: 114.3-406.4mm

welded steel casing and tubing pipes: 88.9-660.4mm

Outer Dimensions: 6.0mm-219.0mm

Wall Thickness: 1.0mm-30 mm

Length: max 12m

The main steel grade of API 5CT:

- API 5CT H40

- API 5CT J55

- API 5CT K55

- API 5CT M65

- API 5CT N80 (1,Q)

- API 5CT L80 (9Cr,13Cr)

- API 5CT C90

- API 5CT T95

- API 5CT P110

- API 5CT Q125

Connections:

API 5CT is applicable to following connections which complied with API SPEC 5B:

- short round thread casing (STC);

- long round thread casing (LC);

- buttress thread casing (BC);

- extreme-line casing (XC);

- non-upset tubing (NU);

- external upset tubing (EU);

- integral joint tubing (IJ).

Groups of Grade:

- Group 1: All casing and tubing in Grades with H, J, K, N and R

- Group 2: All casing and tubing in Grades with C, L, M and T

- Group 3: All casing and tubing in Grade P

- Group 4: All casing in Grade Q

Surface treatment: fusion bond epoxy(FBE) coating,coal tar poxy,3PE,vanish coating,bitumen coating,black oil coating as per customer’s requirement .

Testing: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test,etc.

Application:steel casing pipe is widely used for fastening oil and gas well wall or bore hold,with bigger diameter than tubing pipe,including surface casings,technical casings and oil layer casings.

Packing: Bare/bundles/crates/crate protection at the both sides of tubes or as per customers’ requirements.

API 5CT PLS1 steel casing pipes

Chemical Composition of API 5CT steel casing and tubing pipes:

| Chemical composition,mass fraction(%) | |||||||||||||||

| Group | Grade | Type | C | Mn | Mo | Cr | Ni | Cu | P | S | Si | ||||

| Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Max. | Max. | Max. | Max. | Max. | |||

| 1 | H40 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – |

| J55 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – | |

| K55 | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – | ||||

| N80 | 1 | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – | |

| N80 | Q | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – | |

| R95 | – | – | 0.45 | – | 1.90 | – | – | – | – | – | – | 0.03 | 0.030 | 0.45 | |

| 2 | M65 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – |

| L80 | 1 | – | 0.43 | – | 1.90 | – | – | – | – | 0.25 | 0.35 | 0.03 | 0.030 | 0.45 | |

| L80 | 9Cr | – | 0.15 | 0.30 | 0.60 | 0.90 | 1.10 | 8.00 | 10.00 | 0.50 | 0.25 | 0.02 | 0.010 | 1.00 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1.00 | – | – | 12.00 | 14.00 | 0.50 | 0.25 | 0.02 | 0.010 | 1.00 | |

| C90 | 1 | – | 0.35 | – | 1.20 | 0.25 | 0.85 | – | 1.50 | 0.99 | – | 0.02 | 0.010 | – | |

| T95 | 1 | – | 0.35 | – | 1.20 | 0.25 | 0.85 | 0.40 | 1.50 | 0.99 | – | 0.02 | 0.010 | – | |

| C110 | – | – | 0.35 | – | 1.20 | 0.25 | 1.00 | 0.40 | 1.50 | 0.99 | – | 0.02 | 0.005 | – | |

| 3 | P110 | – | – | – | – | – | – | – | – | – | – | – | 0.03 | 0.030 | – |

| 4 | Q125 | 1 | – | 0.35 | – | 1.35 | – | 0.85 | – | 1.50 | 0.99 | – | 0.02 | 0.010 | – |

- a.The carbon content for L80 may be increased up to 0.50% maximum if the product is oil-quenched.

- b. The molybdenum content for Grade C90 Type 1 has no minimum tolerance if the WT is less than 17,78mm.

- c.The carbon content for R95 may be increased up to0.55% maximum if the product is oil-quenched.

- d.The molybdenum content for T95 Type 1 may be decreased to 0.15% minimum if the WT is less than 17,78mm.

- e. For EW Grade P110,the phosphorus content shall be 0.020% maximum and the sulfur content 0.010% maximum

- NL=no limit.Elements shown shall be reported in product analysis.

Mechanical Properties of API 5CT steel casing and tubing pipes:

| Mechanical Properties | ||||||||

| Group | Steel Grade | Type | Total | Yield Strength (Mpa) | Tensile Strength (Mpa) | Hardness max. | ||

| % | min. | max. | MPa | HRC | HWB | |||

| 1 | H40 | – | 0.5 | 276 | 552 | 414 | – | – |

| J55 | – | 0.5 | 379 | 552 | 517 | – | – | |

| K55 | – | 0.5 | 379 | 552 | 655 | – | – | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | – | – | |

| N80 | Q | 0.5 | 552 | 758 | 689 | – | – | |

| R95 | – | 0.5 | 655 | 758 | 724 | – | – | |

| 2 | M65 | – | 0.5 | 448 | 586 | 586 | 22 | 235 |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | |

| C110 | – | 0.7 | 758 | 828 | 793 | 30 | 286 | |

| 3 | P110 | – | 0.6 | 758 | 965 | 862 | – | – |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | – | |

- a.In case of dispute,laboratory Rockwell C hardness testing shall be used as the referee method.

- b.No hardness limits are specified,but the maximum variation is restricted as a manufacturing control in accordance with API 5CT.

API Spec 5CT standard replaced by:

- API Spec 5CT – Specification 5CT/ISO 11960, Specification for Casing and Tubing, Eighth Edition, Petroleum and natural gas industries-Steel pipes for use as casing or tubing for wells

- This product references:

- API Spec 5B – Specification for Threading, Gauging, and Thread Inspection of Casing, Tubing, and Line Pipe Threads (US Customary Units) (Includes March 2004 Addendum)

- ISO 10422:1993 – Petroleum and natural gas-industries; threading, gauging, and thread inspection of casing, tubing and line pipe threads; specification

- This product replaces:

- API 5CT – Specification for Casing and Tubing (U.S. Customary Units)

- ISO 11960 was prepared by Technical Committee ISO/TC 67, Materials, equipment and offshore structures for petroleum, petrochemical and natural gas industries, Subcommittee SC 5, Casing, tubing and drill pipe.

Haihao Group can supply API 5CT steel casing and tubing pipes in different size,diameters and angles,we are also able to supply casing with non-API specifications for special situations,including those with semi-premium and premium connections.We also can supply seamless steel pipes,ERW/LSAW/SSAW steel pipes,butt welding pipe fittings,forged pipe fittings,forged flanges in different materials,standards.If you want to know more about our piping products,please email us:sales@haihaogroup.com