Comparison of cold-rolled and hot rolled seamless steel pipes and their advantages and disadvantages

There are mainly two kinds of stainless steel seamless steel pipes, namely, cold rolling seamless steel pipes and hot-rolled seamless steel pipes. The difference between them is obvious, each has its own advantages and disadvantages.

Difference between cold-rolled stainless steel seamless steel pipes and hot rolled seamless steel pipes

First, the local buckling of materials. The section of cold rolled stainless steel pipe can have local buckling, so as to make better use of the post buckling bearing capacity of pipes, while the section of hot-rolled stainless steel pipes can not have local buckling.

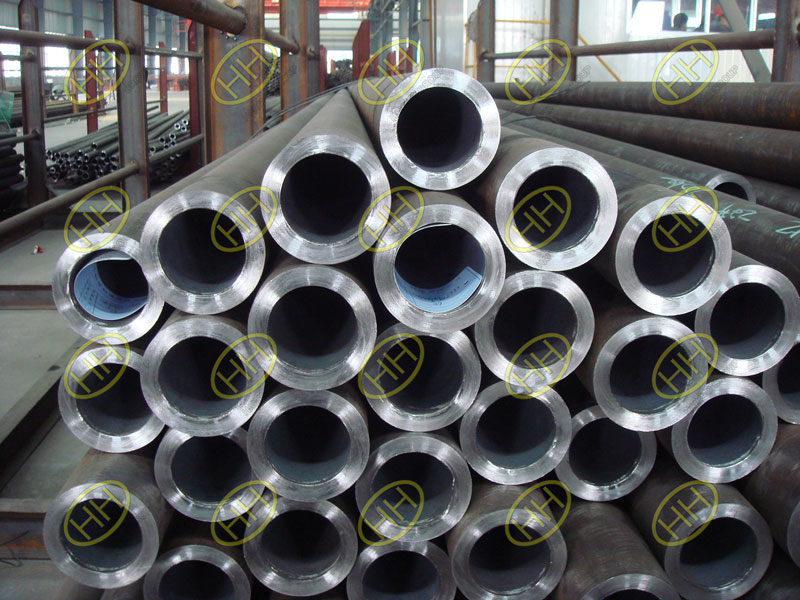

API 5L PSL2 X65 seamless steel pipes

Secondly, the difference of the residual stress is different, so the distribution of the cross section is very different. Residual cold-formed stainless steel on the stress distribution of bending type, and the residual hot rolled steel section stress distribution on the performance of thin film.

In addition, the free torsion stiffness of the hot rolled stainless steel pipe is higher than that of the cold rolled steel, so the torsional resistance of the hot rolled stainless steel pipe is better than that of the cold rolled stainless steel pipe.

Advantages and disadvantages of cold-rolled stainless steel seamless steel pipes and hot rolled seamless steel pipes

The cold rolled seamless steel pipe is made of stainless steel plate or under cold drawing, cold bending, cold drawing and other cold drawing process under the condition of normal temperature. The utility model has the advantages of fast forming speed, high yield, and will not damage the surface coating, can be made into a variety of styles section, which can well meet the various needs of cold rolled stainless steel materials; also can let the formation of plastic deformation, so as to improve the material yield point.

Q345B 16Mn seamless steel pipes

There are three main shortcomings. One is that although there is no hot plastic compression in the forming process, there will still be residual stresses in the section, which will inevitably affect the overall and local buckling characteristics of stainless steel. The other is the style of cold rolled stainless steel is usually the open section, resulting in the lower free torsion stiffness of the section, which is prone to torsion when bending, and it is prone to bending torsion buckling when it is subjected to compression, and the torsion resistance is weak. The third is that the cold rolled stainless steel has low wall thickness and is not thickened at the corner of stainless steel plate joining, resulting in poor performance of local concentrated load.

Compared with hot-rolled seamless steel pipes, cold rolled seamless steel pipes are rolled under the recrystallization temperature of materials, while hot-rolled seamless steel pipes are rolled on the recrystallization temperature.

The advantage is that it can refine the microstructure of stainless steel, destroy the casting structure of the ingot, and remove the microstructural defects, make the steel structure more dense and improve its mechanical properties. This improvement is mainly along the rolling direction, so that the stainless steel material is not isotropic to a certain extent, bubbles, cracks and loose in the previous pouring, will be welded by effect of high temperature and pressure.