Ensuring quality: a guide to the types of pipe fitting coating inspections

Pipe fitting coatings play a vital role in ensuring the longevity and functionality of the fittings. However, the quality of the coatings is equally important. To ensure the highest quality of coatings, our company employs various quality inspection types.

Firstly, we perform visual inspections to ensure that the coatings are evenly applied and free of any physical defects. We also use ultraviolet (UV) lights to detect any pinholes or other defects that may not be visible under normal lighting.

3LPE Coated 90 Degree Elbows and 45 Degree Elbows

Secondly, we use adhesion tests to check the bond strength of the coating to the surface of the fittings. This test is crucial to ensure that the coating remains intact and provides adequate protection against corrosion and other environmental factors.

Thirdly, we use salt spray tests to simulate harsh environmental conditions and test the corrosion resistance of the coatings. This test involves exposing the coated fittings to a saltwater mist and monitoring any signs of corrosion.

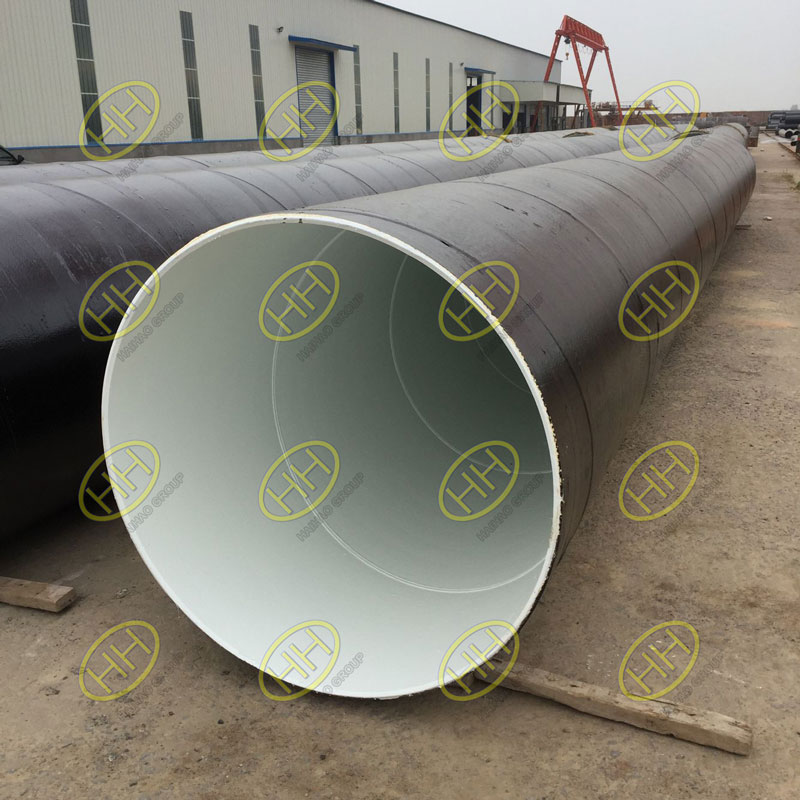

3PE steel pipes

Lastly, we use thickness measurements to ensure that the coatings meet the required thickness specifications. This is important as the thickness of the coating directly affects its ability to protect the fittings against corrosion and other environmental factors.

By employing these various quality inspection types, we can ensure that our pipe fitting coatings meet the highest standards of quality and durability. Our commitment to quality has earned us a reputation for providing reliable and long-lasting pipe fittings.