Forged flanges

Haihao Group supply forged flanges more than 30 years,as one of the earliest flange manufacturer we have strong experience in forged flange production and inspection.We have a complete set of equipment including advanced cutting,forging,machining,drilling machines and professional testing & inspection instruments.

Forged flanges

Specifications of forged flanges:

Most forged steel flanges correspond to the requirements of the American Standards Association(ASME/ANSI Standard B16.5)and the ASTM specification A105,A350,A182,A694.We supply flange size from 1/2″-192″(DN15″-DN4800).

The following types are manufactured and stocked:

Weld Neck Flange |

Weld neck flanges,available in all pressure ratings and sizes,are butt-welded to the end of the pipe, and are usually specified when service conditions are severe and excellent workmanship necessary. Since the inside diameter of the flange must match that of the pipe, the flange bore should be specified in ordering. |

Slip On Flange |

Slip-on flanges,also available in most pressure ratings and sizes,are a popular type due to their ease of application. This flange slips over the end of the pipe and is usually set so that the flange face is about 9.5mm beyond the end of the pipe. This permits double-welding of the flange – one strength fillet weld to join the hub of the flange to the pipe, and a seal fillet weld inside the flange at the end of the pipe. Where operating conditions permit, the seal weld is omitted. |

Blind Flange RF |

Blind flanges,available in all sizes and pressure ratings, are solid forgings used to close off the end of a piping system and to gain easy access to the interior of the line. |

Threaded Flange |

Threaded flanges(or screwed flange) are attached to the pipe like any other screwed fittings, and may be back-welded to seal the joint between pipe and flange. Although still available in most sizes and pressure ratings, screwed fittings today are used almost exclusively in smaller pipe sizes and at low pressures. |

Lap Joint Flange |

Lap joint flanges are used on piping equipped with lap joint stub ends or with lapped pipe. They may be used at all pressures and are available in a full size range. These flanges slip over the pipe, and are not welded or otherwise fastened to it;bolting pressure is transmitted to the gasket by the pressure of the flange against the back of the pipe lap. |

Socket Weld Flange |

Socket weld flanges contain a recess in the back of the flange to receive the end of the pipe, which is attached by a fillet weld around the hub of the flange. Since socket-welding connections are not as strong as butt-welded joints, the use of this type of flange is almost always confined to NPS 4 (DN 100) and smaller sizes, and to the lower pressure ratings. Its chief advantage lies in the ease of preparation and installation. |

Flat/Plate Flange |

Plain flange(plate flange) is also called flat flange,plate slip on flange or a ring flange.It looks like a flat circular disk with inner bore and bolt holes on it.It is one kind of the slip on flange. |

Long Weld Neck Flange |

Long weld neck flanges are used primarily for outlets for vessels and tanks.Drilled to ANSI Standards, they are forged with long,heavy-wall, straight hubs, and finished with square cut ends. |

Reducing Flange |

Reducing flanges are available,we can supply the reducing flange in various types including weld-neck reducing flange,slip on reducing flange,threaded reducing flange and plain reducing flange etc. |

Orifice flange |

Orifice flanges are used for measuring fluid flow in piping systems. Their design conforms to the recommendations of the American Gas Association’s Committee on Gas Measurement. Commonly furnished as either welding neck or slip-on type, they may also be ordered as screwed flanges. Orifice unions are available in Class 300 (PN 50) and heavier pressure ratings. |

Spectacle Blind Flange |

Spectacle blind flange(spectacle flange) is also called figure-8 blind flange,it is made of two pieces metal discs which are joint together by a part of steel handle. The spectacle blind flange is a safety device used to isolate a section of pipeline or equipment when they need to be inspected or removed from piping system.It is not like a valve,the spectacle blind flange is a permanent or long term isolation block. |

Nipoflange |

Flangeolet (flange-outlet) is also called nipoflange or weldoflange,its shape looks like a long weld neck flange.It could be regarded as a combination of a long weld neck flange and a weldolet,or a nipolet welded with a weld neck flange. |

Anchor Flanges |

Anchor flange is a device to restrain pipe movement in a piping system,it looks like a weld neck flange but has two hubs on the both sides to weld with the pipes,but there is no bolt bores on the anchor flanges. |

Rolled Ring Flange |

Rolled-forging ring flange produced by Haihao Group means the large size ring flanges produced by rolled forging,not the open die forging process.From the shape,it is a customized flange of plain type,weld neck shop or other types,and always have a large diameters. |

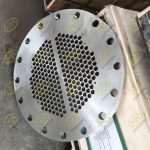

Tubesheet |

Tube sheet is usually made from a round flat piece of plate,sheet with holes drilled to accept the tubes or pipes in a accurate location and pattern relative to one another.The tube sheets are used to support and isolate tubes in heat exchangers and boilers or to support filter elements.Tubes are attached to the tube sheet by hydraulic pressure or by roller expansion. |

Non-standard Flange |

Non-standard flange is also called custom flange,it means the flange is not as per the international standard of flanges.Commonly it is designed for special application. |

Large Diameter Flange |

Large diameter flanges,in sizes beyond the B16.5 range,are available for special installations. Dimensions given herein are those most commonly used;however, flanges and rolled rings for large diameter pipe or for vessels and tanks can readily be made to other specifications. |

Materials of forged flanges:

A105 – Carbon grades for high temperature service

A181 – Carbon grades for general service

A182 – Alloy and stainless grades for high temperature service

A350 – Carbon and alloy grades for low temperature service

A694- Carbon and alloy grades for high temperature service

Carbon steel:ASTM A105,A350 LF2,SS400,P235GH,P250GH,C22.8,Q235,20#,16Mn.

Stainless steel:ASTM A182 F304,F304L,F316,F316L,F321,F347,F310,F44,F51 etc.

Alloy steel:ASTM A694 F42,F46,F52,F56,F60,F65,F70,A182 F5,F9,F91,F12,F11,F22 etc.

Standards of forged flanges:

- ANSI/ASME B16.5,B16.47,B16.48,

- AWWA C207,

- API 6A/6B/6BX,

- DIN 2527,DIN 2573,DIN 2576,DIN 2631,DIN 2632,DIN 2633,DIN 2634,DIN 2635,DIN 2566,DIN 2642,

- EN 1092,

- BS 4504,

- JIS B2220,

- GOST 12820,GOST 12821,

- SABS 1123,

- AS 1219 etc.

Forged flanges applications:

Forged flanges are used as a connection component for pipes,valves, pumps and other equipment to form a pipework system. They provide easy access for cleaning, inspection, modification or repairs.Flanges are usually welded onto pipes or screwed onto a threaded pipe end and then joined with bolts to make the connection.

Haihao Group manufacture & supply & export forged flanges more than 30 years,if you want to know more about our forged flanges,please email us:sales@haihaogroup.com