Introduction of ASME B16.11 socket welding fittings

What are ASME B16.11 socket welding fittings?

Socket welding is a pipe connection in which pipes are inserted into the wall of a valve,fitting or flange and welded.In contrast to butt welding,socket welding is usually used for small diameter pipes of 2 inches or less.Socket welding pipe fittings are one type of the forged pipe fittings.We manufacture socket welding fittings according to ASME B16.11 standard or customers’ requirements.Soeket welding pipe fittings contain 45 degree/90 degree elbows,tees,crosses,coupling,half-coupling,cap,etc.

Socket weld ASTM A105 45 degree elbows

Socket welding adopts fillet weld.When high structural strength requirement and high leakage risk become design considerations,socket welding welded joint is a better choice.The fatigue strength of socket welds is lower than that of butt welds due to the use of fillet welds and abrupt changes in geometry.However,socket welded joints are superior to other mechanical link joints.

Socket welded pipe fittings are a group of high-pressure pipe fittings applied in various industrial production processes,and their characteristics are as follows:

(1)For conveyance of leakage-free flammable media,toxic or expensive media, and steam from 300PSI to 600PSI.

(2)Only connect with ASME pipe,same diameter.

(3)It is used for permanent operation of pipelines and provides better flow characteristics.

(4)The material is ASTM material and its manufacturing standard is ASME B16.11.B16.11 covers pressure-temperature ratings, dimensions, tolerances, marking and material requirements for carbon, stainless and alloy steels. The material form of optional material is forgings, round bars and seamless tubes. The commonly used materials are ASTM A105,ASTM A182 or ASTM A350.

(5)Socket welded pipe fittings have three pressure classes: Class 3000,6000 and 9000.

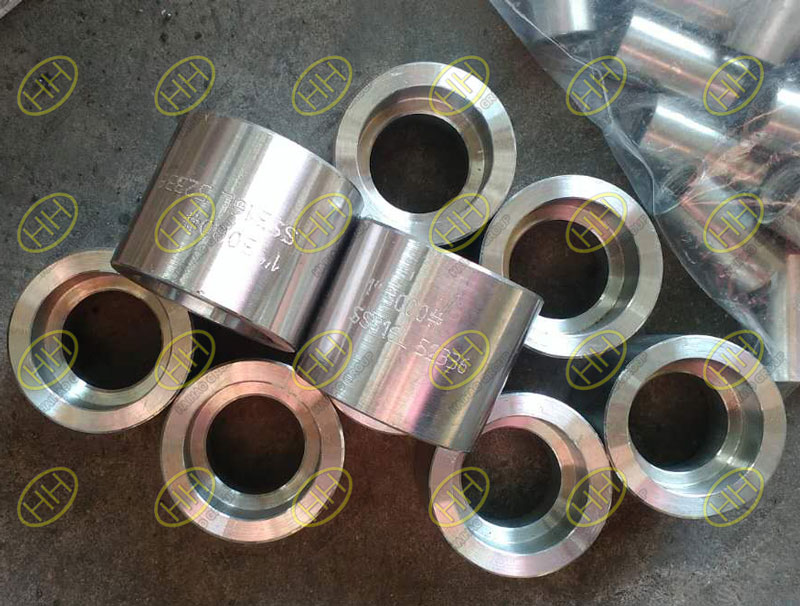

ASTM A182 F316L Socket Weld Couplings

Advantages of socket welded pipe fittings:

(1) the pipe need not be preformed groove.

(2) do not need to calibrate the spot welding, because the pipe itself plays a calibration role.

(3) the welding material will not penetrate into the pipe hole.

(4) can replace the threaded pipe fitting, thus reducing the risk of leakage.

(5) the fillet weld is not suitable for X-ray inspection, so correct pipe fitting and welding are crucial. Magnetic particle detection and penetration detection are commonly used for surface detection of fillet welds.

(6) construction cost is usually lower than butt welding joint. The reason is that there is no need for groove assembly and groove prefabrication.

Defects of socket welded fittings:

(1) the welder shall ensure a 1.6mm welding expansion gap between the pipe and socket shoulder during welding.

(2) the existence of cracks in welding gaps and socket welds reduces the corrosion resistance or radiation resistance of pipes. When solids build up at socket welding joints, they can cause problems in pipe operation and maintenance. In this case, a full penetration butt weld is usually required for the entire pipe.

(3) socket welding is not suitable for ultra-high pressure food industry. Because it is not fully welded through, there are overlaps and cracks, it is difficult to clean,forming a false leak.

Haihao Group manufacture ASME B16.11 socket welding fittings in different materials such as carbon steel(ASTM A105,ASTM A350 LF2,etc),stainless steel(ASTM A182 F304,F304L,F316,F316L,F321,F347,etc),alloy steel(ASTM A182 F1,F5,F9,F11,F22,F91,ASTM A694 F42,F46,F52,F56,F60,F65,F70,etc).We also can supply butt welding pipe fittings,steel pipes and flanges.If you want to know more about our pipeline products,please email us:sales@haihaogroup.com