Ensuring quality and safety: inspection procedures for coated steel pipes

Coated steel pipes undergo a rigorous inspection process to ensure their quality and reliability. These pipes, which are coated with a layer of protective material on their inner or outer surfaces, play a crucial role in various fluid transportation applications. Here’s an overview of the inspection procedures involved in producing high-quality coated steel pipes:

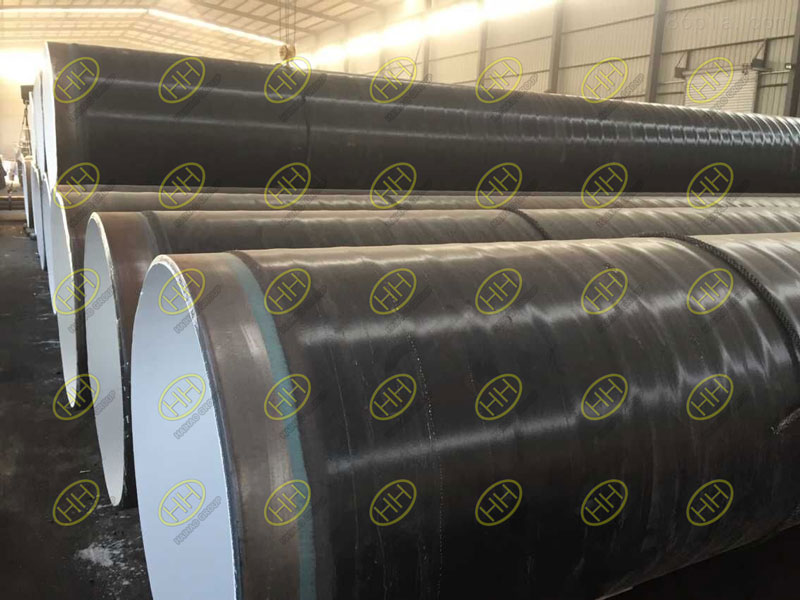

3PE anti corrosion coated steel pipes

Visual Inspection: The first step involves a visual examination of the pipe’s surface to detect any visible defects such as scratches, bubbles, or impurities.

Thickness Measurement: Using a thickness gauge, the thickness of the coating is measured at multiple points to ensure it meets the required specifications.

Adhesion Testing: The adhesion between the coating and the steel surface is tested to assess the likelihood of delamination or peeling.

Corrosion Resistance Testing: Various methods, including salt spray and acid tests, are employed to evaluate the pipe’s resistance to corrosion.

Abrasion Resistance Testing: The pipe’s resistance to wear is assessed using a friction testing machine to ensure its durability during long-term use.

High-Temperature Stability Testing: Pipes are exposed to elevated temperatures to assess their resistance to deformation or detachment.

Bend Performance Testing: The pipe’s ability to withstand bending without cracking or delamination is evaluated.

Flame Retardancy Testing: The pipe’s flame retardant properties and performance during exposure to flames are examined.

Non-Destructive Testing: Techniques such as X-ray and ultrasonic testing are used to detect internal defects or inclusions.

Strength Testing: The tensile strength and yield point of the coated steel pipe are determined using a tensile testing machine.

These comprehensive inspections ensure that coated steel pipes meet the highest quality and safety standards as required by relevant specifications and regulations. At every stage of production, we prioritize quality control to deliver reliable and durable products to our customers. Trust in us for your coated steel pipe needs, knowing that we prioritize quality, safety, and compliance with industry standards.