Introduction of Polyurethane Piping Coating or Lining

Polyurethane is often used for piping coating or lining because polyurethane materials have following advantages:

- Fast curing – ensures economy of high production rates and efficiency.

- Excellent adhesion to ferrous and properly prepared steel surfaces.

- High impact resistance

- Lower lining thickness is required compared to other technologies, and hence pipe design can be more efficient, reliable and economical as the wastage factor will be reduced, and pipeline capacity is higher for the same size of pipe.

- Reduced head loss and pumping losses due to a smoother internal surface of the pipes.

- Longer economic life as deterioration due to erosion cavitation is low.

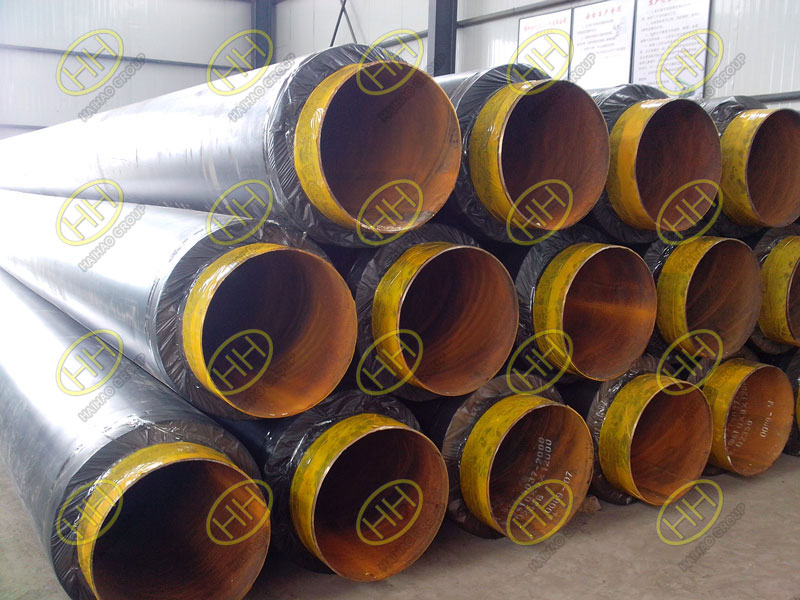

Insulation steel pipes

But there are some limitations associated with polyurethane material when used for lining steel water transmission pipe. Polyurethanes require heated, plural-component equipment and qualified, experienced applicators. Polyurethane coatings require that the host pipe be thoroughly cleaned and for in-service pipe that includes removal of hard deposits, nodules, scale, corrosion and other debris and be substantially dry prior to application of the coating to ensure good adhesion between the liner and the pipe wall. Voids and blisters may form if the pipe is not properly prepared and there is a potential for uneven liner thickness due to inconsistencies in dual material component pumps associated with the application equipment.

If you have any demand for piping goods of polyurethane coating or lining,contact Haihao Group for more information.Email:sales@haihaogroup.com