-

At Haihao Group, we take immense pride in serving our global clientele with premium piping solutions. We are delighted to share the news of a recent order from our esteemed Pakistani client who has chosen to enhance their projects with our top-of-the-line ...

-

When it comes to steel pipes, understanding their hardness is essential for various applications. Steel pipe hardness is a key factor in determining their suitability for specific uses. There are several methods to assess the hardness of steel pipes, each ...

-

In the intricate network of maritime pipelines, the reliable transport of various fluids is crucial to ensure the seamless operation of marine machinery, guaranteeing the safety of every voyage. A ship is a complex amalgamation of diverse pipelines, each s ...

-

In recent days, the futures price index for coal, coke, and steel has been on a continuous decline since September 25, extending this downward trend into the first trading day after the National Day holiday. Notably, iron ore, rebar, and hot-rolled coil fu ...

-

In the realm of pipe bending, a myriad of processes is employed to elevate the quality of pipe components, making them suitable for a wide range of applications. Moreover, while maintaining their existing capabilities, further enhancements are feasible. Le ...

-

Stainless steel seamless steel pipes are versatile and widely used in various industries. They are known for their corrosion resistance, durability, and strength. These pipes are available in different materials and standards, ensuring compatibility with d ...

-

Haihao Group, a trailblazer in providing top-tier piping solutions, proudly announces the signing of a substantial supply agreement with a prominent domestic shipyard. The esteemed client has placed an order for over a thousand components, including seamle ...

-

Stainless steel bent tubes are a valuable component in various industries, known for their durability and resistance to corrosion. To ensure these tubes maintain their pristine condition and quality, proper storage is essential. Here, we outline the best p ...

-

At Haihao Group, we take immense pride in our ability to deliver precision-engineered piping solutions that meet and exceed our clients’ expectations. Our commitment to quality, attention to detail, and unwavering dedication to customer satisfaction ...

-

Haihao Group is delighted to announce the successful delivery of the final batch of products for Shunzhou Shipyard, marking the completion of a successful collaboration. This shipment includes critical components designed for the ship’s main deck fue ...

-

Not long ago, a customer in Singapore ordered a batch of pipe unions from Haihao Group.Pipe unions are essential components in pipeline systems, offering convenient and efficient solutions for installation and disassembly. They consist of three main parts: ...

-

Haihao Group has been committed to providing high-quality pipe and fitting solutions to global customers. Recently, we have completed the preparation of a batch of pipe bends for a Saudi customer by using a medium-frequency pipe bender. The medium-frequenc ...

-

At Haihao Group, we take pride in our commitment to supplying top-quality industrial components worldwide. Recently, we had the privilege of serving our valued client in Bulgaria, delivering a range of meticulously crafted carbon steel flanges. These flang ...

-

In yet another demonstration of our commitment to customer-centric solutions and efficient service, Haihao Group is thrilled to announce the successful fulfillment of an additional order from our esteemed client in Singapore. This small but significant ord ...

-

Haihao Group is proud to offer our esteemed Spanish customer the finest P265GH elbows, flanges, and other products for their ship’s piping system. P265GH is a remarkable pressure vessel steel renowned for its exceptional properties that make it the i ...

-

We are thrilled to announce that Haihao Group has recently partnered with a valued Spanish customer to supply EN 10253-2 standard 90-degree LR elbow 1.5D P265GH for their local ship’s crucial fire-fighting piping system. At Haihao Group, we take imme ...

-

In today’s ever-evolving industrial landscape, safety, and compliance have become paramount concerns for businesses worldwide. When it comes to the marine and offshore sectors, adhering to international standards and certifications is not just essent ...

-

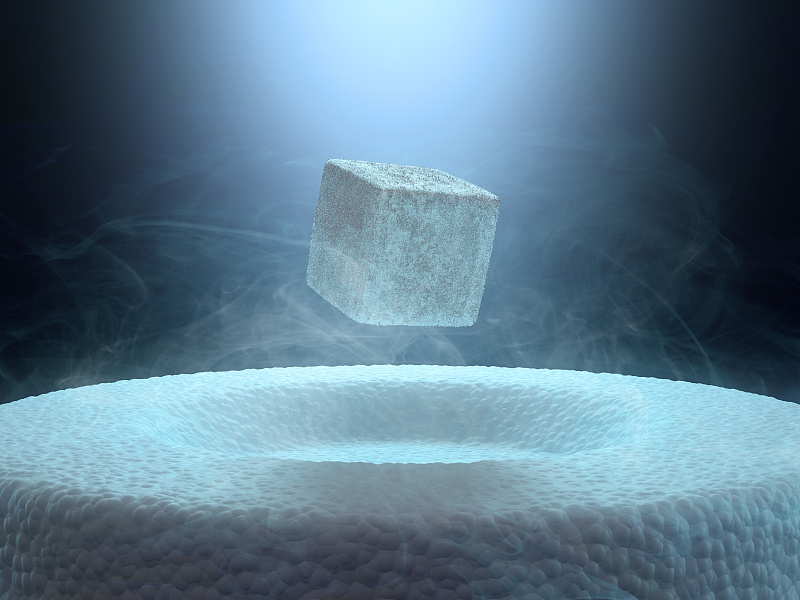

Recent claims by scientists in South Korea about achieving room-temperature superconductivity have generated considerable excitement and sparked global interest in scientific research. Although the findings are yet to be independently verified, the possibi ...

-

Haihao Group takes immense pride in fostering collaborative partnerships that drive innovation and shape the future of industries. In a recent development, Mr. Zhang, General Manager of Haihao Group, embarked on an insightful visit to China First Heavy Ind ...

-

In the world of pipeline fittings, tees play a pivotal role in diverting the flow of fluids, making them indispensable components in various industries. Two commonly used types of tees are seamless tees and welded tees. While both serve the same fundamenta ...