Something you should know about pipeline anti-corrosion processing

The pipeline anti-corrosion processing generally refers to external coating and internal coating.The external coating is mainly used for anti-corrosion protection for liquid pipes before burying,and internal coating is mainly used to reduce the investment and maintenance costs.There are many ways,like petroleum asphalt,PE jacket and PE foam jacket,epoxy coal tar pitch,coal tar enamel,epoxy powder and three layer composite structure,epoxy coal tar pitch cold tape(PF type),rubber plastic epoxy coal tar pitch cold wrapping (RPC type) and so on.At present, the most widely used pipeline anti-corrosion methods are FBE,2PE/PP,3PE.(Types of pipeline coating and its advantage and disadvantage)

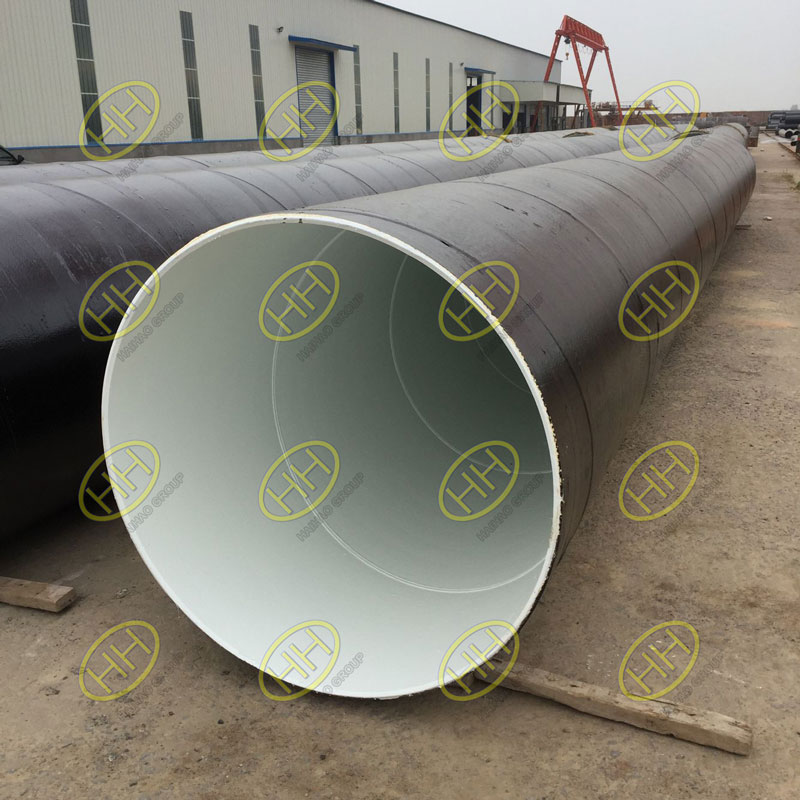

3PE steel pipes

3PE coating pipe

A-The more common external coating is FBE,2PE,3PE and so on.

1. Single-layer FBE coating

Characterized by excellent corrosion-proof performance, insulativity and relatively long service life, epoxy powder coating is one of the most advanced outer anticorrosive coating of pipeline. there are normal type and strengthened type. thickness normal type: 300-400μm,strength type: 400-500μm.

2. 2PE/2PP coating

Two-layer PE/PP coating is characterized by excellent corrosion-proof performance, insulativity, relatively long service life and mechanical damage resistance. there are normal type and strengthened type. the thickness varies with the specification shift of steel pipe: thickness min of normal type: 1.8 mm, thickness min of strengthened type: 2.5 mm.

3. 3PE/3PP Coating

Three-layer PE/PP coating is characterized by excellent corrosion –proof performance,insulativity,relatively long service life and mechanical damage resistance.It is widely used in coating for all kinds of major pipeline engineering. there are normal type and strengthened type the thickness varies with specification shift of steel pipe: thickness min of Normal type: 1.8 mm; thickness min of strengthened type: 2.5 mm.

We offer inside corrosion protection for DN 100-DN 1500 steel pipes, the paint designated by clients.

FBE coating for steel pipe

FBE coating pipe

The properties of anti-corrosion coating 3PE/3PP.

| Item | Property Index |

| Peel Strength (N/cm))

20±5℃ 50±5℃ |

≥60 ≥40 |

| Cathodic stripping (mm)

(65℃,48th) |

≤10 |

| Impact strength (J/mm) | ≥5 |

| Anti-bending (2.5°) | Polyethylene without cracking |

Thickness of 3PE/3PP

| Steel pipe DN | thickness of epoxy (μm) | Adhesives(μm) | thickness of coating (mm) | ||

| 1 | 2 | 3 | |||

| DN≤100 | 60-80 | 170-250 | 1.0 | 1.8 | 2.5 |

| 100<DN≤250 | 1.2 | 2.0 | 2.5 | ||

| 250<DN≤500 | 1.5 | 2.2 | 3.0 | ||

| 500<DN≤800 | 2.0 | 2.5 | 3.5 | ||

| DN≥800 | 2.2 | 3.0 | 3.5 | ||

B-Internal coating corrosion protection of steel pipes:

Hebei Haihao Group offer internal corrosion protection for DN 100-DN 1500 steel pipes,like PE lining,cement mortar lining,ceramic lining,or the paint designated by clients.

There are many ways of pipeline anti-corrosion processing,and also changes according to the site construction situation,environment,temperature and so on.Hebei Haihao Group provides a full range of solutions.

Reference:

- NF A 49-710: External Triple-layer polyethylene based coating(French)

- NF-A 49-709: STEEL TUBES. EPOXY RESIN, EPOXY PITCH AND POLYURETHANE PITCH – BASED LIQUID PAINT INTERNAL COATINGS. APPLICATION INSPECTION AND TESTING

- DIN 30670-2012: Polyethylene coatings for steel pipe and fittings

- CAN CSA-Z245. 21-M92:External Polyethylene Coating for Pipe (Canada)

- CAN CSA –Z245.20-M92:External Fusion Bond Epoxy Coating for steel pipe (Canada)

- AP RP 5L2: Recommended Practice for internal coating of line pipe for Non-corrosive Gas Transmission Service

- ANSI/AWWA C213-15:Fusion-Bonded Epoxy Coating for the Interior and Exterior of Steel Water Pipeline

- ANSI/AWWA C210-15:Liquid Epoxy Coating Systems for the interior and Exterior of Steel Water Pipelines