The difference between seamless tee and welded tee in the production process

In the world of pipeline fittings, tees play a pivotal role in diverting the flow of fluids, making them indispensable components in various industries. Two commonly used types of tees are seamless tees and welded tees. While both serve the same fundamental purpose, they differ significantly in their production processes.

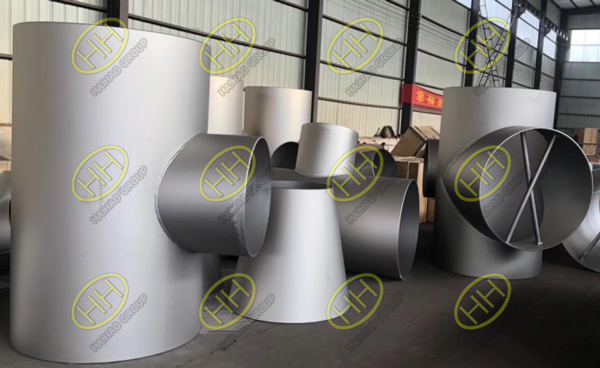

Equal Tees BS1965 P265GH

Seamless Tee:

Seamless tees are crafted from a single piece of metal without any welding or joint. The manufacturing process begins with a solid cylindrical billet, which is then heated and pushed through a piercing rod to create a hollow tube. Next, this tube is further heated and stretched to achieve the desired tee dimensions.

Key Advantages:

Enhanced Strength: Seamless tees offer superior strength and structural integrity due to their uninterrupted grain flow, making them ideal for high-pressure and high-temperature applications.

Aesthetically Pleasing: The absence of weld seams gives seamless tees a smooth and polished appearance, contributing to a sleek and professional look in pipeline installations.

Reduced Risk of Leakage: Seamless tees eliminate the potential weak points that could arise from welding, minimizing the risk of leakage or failure in critical systems.

Welded tee with U-shape welding and V-shape welding

Welded Tee:

Welded tees are formed by joining two or more pieces of metal through various welding techniques. The process involves cutting the material into tee-shaped sections and welding them together to create the final product.

Key Advantages:

Cost-Effective: Welded tees generally have lower production costs compared to seamless tees since they are made from smaller pieces of material and require less complex manufacturing processes.

Availability in Diverse Materials: Welded tees can be fabricated from a wide range of materials, offering versatility in meeting different project requirements.

Suitable for Non-Critical Applications: While welded tees are durable and reliable, they are often preferred for non-critical systems where lower pressure and temperature conditions are involved.

Choosing the Right Tee for Your Project:

The decision between a seamless tee and a welded tee depends on the specific needs of your pipeline project. Here are some guidelines to consider:

High-Pressure Systems: For applications involving high pressure and temperature, seamless tees are the preferred choice due to their superior strength and integrity.

Critical Installations: In critical systems where leakage or failure could have severe consequences, seamless tees offer a higher level of reliability and safety.

Budget Constraints: If budget is a primary concern and the application involves lower pressure and temperature requirements, welded tees may offer a cost-effective solution.

At Haihao Group, we understand the significance of choosing the right pipe fittings for your projects. With our wide range of ASTM A234 Gr WPB seamless and welded tees, we stand ready to provide you with high-quality solutions tailored to your specific needs. Empower your pipeline projects with our premium fittings and elevate performance, efficiency, and safety to new heights. Contact us today to explore our comprehensive product offerings and experience excellence in pipeline fittings.