What’re different types of flanges and welding methods?

Hebei Haihao Group supplies a wide range of quality industrial forged steel flanges including slip-on flanges, socket weld flanges, blind flanges and other shapes for connection applications in the oil, gas, chemical, wind, pharmaceutical and other industries, manufactured in accordance with ASTM, ANSI, ASME, API and other standards.

Forged flanges are used as a connection component for pipes, valves, pumps and other equipment to form a pipework system. They provide easy access for cleaning, inspection, modification or repairs. Flanges are usually welded onto pipes or screwed onto a threaded pipe end and then joined with bolts to make the connection. The types of flanges are described and shown below:

WELD NECK RING FLANGE (WNRF)

Weld neck flange

Weld neck flanges are circumferentially welded at the neck where the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is durable in critical applications.

SLIP-ON RING FLANGE (SORF)

Slip on flange

Slip-on flanges are fitted over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications.

BLIND RING FLANGE (BLRF)

Blind flange

Blind flanges are used to blank off pipelines, valves and pumps. They can also be used as an inspection cover. It is sometimes referred to as a blanking flange.

SOCKET WELD RING FLANGE (SWRF)

Socket weld flange

Socket weld ring flanges are counter-bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same to provide good flow characteristics.

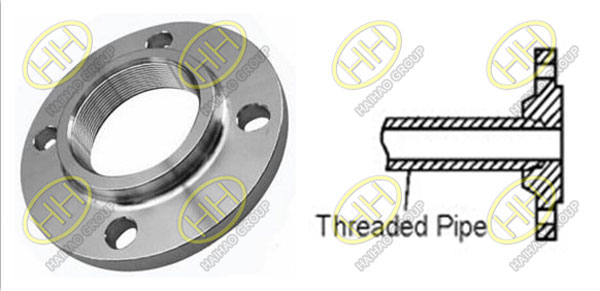

THREADED RING FLANGE

Threaded flange

Threaded flange are referred to as either threaded or screwed. They are used to connect other threaded components in low pressure, non-critical applications. No welding is required.

LAP JOINT RING FLANGE (LJRF)

Lap joint flange

Lap joint flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. A lap joint is used in low pressure applications because it is easily assembled and aligned. To reduce costs, these flanges are supplied without a hub.

RING TYPE JOINT FLANGE (RTJF)

Ring type joint flange

Ring type joint flanges are used to ensure a leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.