Characteristics of deep sea pipeline steel pipe

There is a big difference between submarine pipelines and land pipelines. In addition to the working loads borne by the pipelines during normal operation, the submarine pipelines also need to consider the tensile buckling stress and residual stress after the pipeline is laid, as well as the impact of environmental loads on the pipelines during operation, such as translation and vibration caused by external water pressure, wind, wave, undercurrent, earthquake, etc.

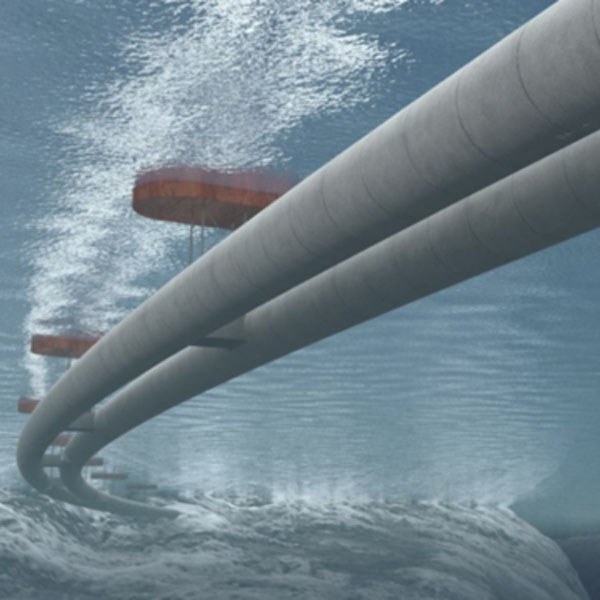

deep sea pipeline steel pipe

In order to adapt to the installation requirements and service conditions of submarine pipelines, the requirements for composition design and performance of submarine pipelines are stricter. The main characteristics are: high deformation strengthening index and uniform elongation; Low yield ratio; Excellent longitudinal tensile property; Low billet central segregation, good thickness direction performance, low fracture separation and lamellar tearing probability; Excellent Charpy impact, drop weight tear and CTOD properties; Excellent weldability; Strict dimensional deviation and precision control. To ensure that the steel pipe has the above properties, its chemical composition design features: low carbon content, low carbon equivalent, low sulfur and phosphorus content, and its rolling process is TMCP.

steel pipe delivery

Haihao Group has been specialized in the production and operation of pipeline engineering supporting products for more than 40 years. We use domestic high-quality raw material steel plates with excellent performance and fracture toughness, which can fully meet the service performance of deep-sea pipelines. At present, various pipeline engineering supporting products such as flanges, steel pipes, elbows, tees, etc. of Haihao have been exported to more than 100 countries and regions around the world. Through market assessment, Haihao products have been well received by customers. We support non-standard customization and prefabrication, and welcome customers who need to consult and purchase.