Effect of heat treatment on the surface quality of stainless steel pipe fitting

The surface of stainless steel pipe fitting is not uniform. When heat treatment is heated, it is necessary to make the oxide skin evenly. To reach the first, the quality of the surface of the stainless steel pipe fitting is mainly determined by the acid washing process after heat treatment. This article focuses on the relationship between surface quality and heat treatment of stainless steel pipe fitting.

1. If the surface of the pipe fitting is attached to oil when heated, the thickness of the oxide scale and the thickness and composition of the oxide scale of the oil attachment part will be different and produce carburizing. The oxidized carburized part of the matrix metal will be severely eroded by acid. The oil droplets ejected from the heavy oil burner when burning first, if attached to the pipe fitting fittings, will also have a great influence. The fingerprints of the operator will also be affected when they are attached to the pipe fitting fittings. So, do not touch the stainless steel directly by hand, do not touch the tube on the surface of the new oil pipe fitting, such as the lubricating oil that is attached to cold processing. It must be cleaned with warm water after the degreasing agent, caustic sodium solution is fully defatted, and then the heat is then carried out.

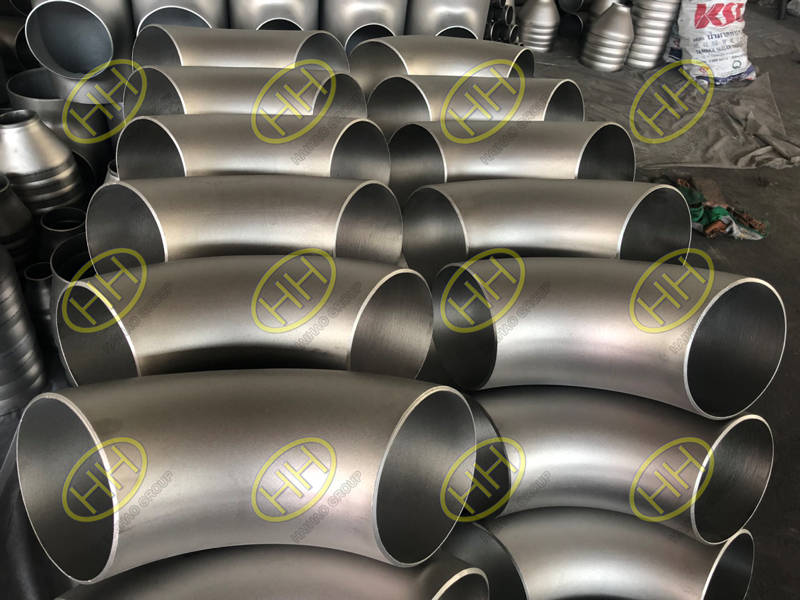

Stainless steel 90 degree elbows

2.If there is any debris on the surface of the pipe fitting, and when it is not organic or ash attached to the pipe fitting, heating will certainly affect the oxide scale.

3.Gas or oil flame directly contacts the stainless steel surface and does not touch the place produced by the oxide scale is different. Therefore, when heating, the processing parts must not be directly exposed to the flame port.

4.If there is a residual oxide skin in the part of the processing part before heat treatment, the remaining parts of the oxide skin and the part without the oxide skin after heating, the thickness and the difference in the composition of the oxide skin will appear, and the surface is not uniform after the acid washing, so the final heat treatment should be paid attention to, but also the intermediate heat treatment and the acid washing should be paid attention to.

ASME B16.9 ASTM A403 WP304L reducing tees

5.If the surface finish is different, if the surface finish is different, even if the same heat is applied, the surface roughness and fine oxide scale are different. For example, the condition of forming oxide scale is different in the place where the partial defects are cleared and uncleaned, resulting in uneven surface of the pipe fitting after pickling.

6.The difference of the atmosphere in the furnace is different from that in the furnace. The formation of the oxide scale will also change. This is also the reason why the acid washing is uneven. Therefore, when heating, the atmosphere in all parts of the furnace must be the same. So it is necessary to consider the cycle of the atmosphere.