How much do you know about stainless steel products?

Stainless steel products are widely used in our life and industry.Do you know the characteristics of stainless steel? Please come with Haihao Group to learn some knowledge of stainless steel.

Stainless Steel Weld Neck Flanges

General characteristics of stainless steel:

- 1.Beautiful surface and diverse use possibilities

- 2.Good corrosion resistance, longer lasting than ordinary carbon steel

- 3.High strength, so the possibility of using thin plates is high

- 4.Resistant to high temperature oxidation and fire

- 5.Normal temperature processing, that is, easy plastic processing

- 6.Easy maintenance because no surface treatment is required

- 7.High finish

- 8.Good welding performance

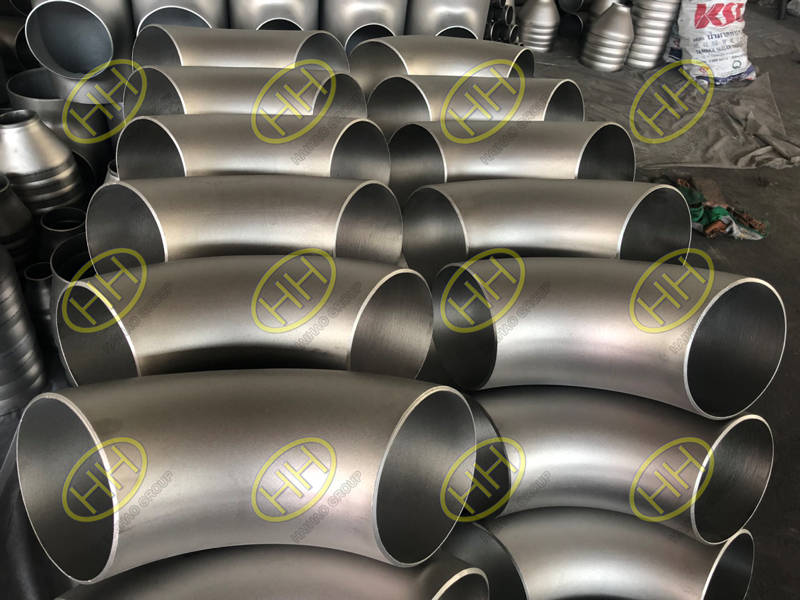

Stainless steel 90 degree elbows

Stainless steel processing and construction:

Bending processing: the sheet can be bent to 180°,but in order to reduce cracking of the surface with the radius of curvature is preferably 2 times the thickness of a thick plate rolling direction 2 times the radius of the plate thickness,the rolling perpendicular to a direction of bending A radius of 4 times the plate thickness is necessary. Especially during welding, in order to prevent processing cracks, the surface of the weld zone should be ground.

Punching: Because stainless steel has higher strength than ordinary materials,higher pressure is required during punching and cutting. The knife-to-knife gap can not be cut and hardened. It is best to use plasma or laser cutting,and necessary heat treatment when gas cutting or arc cutting is used.

Welding: Before welding,embroidery,oil,gouache,paint,etc. That are harmful to welding should be completely removed. Select a welding electrode suitable for the steel type. The spot welding time interval is shorter than the carbon steel spot welding interval. A stainless steel brush should be used when removing the slag. After welding, in order to prevent local corrosion or strength reduction,the surface should be polished or cleaned.

Construction attention points:

In order to prevent scratches and pollutants from adhering during construction, stainless steel is applied under the film. However, as time goes on, the residue of the paste solution is based on the use life of the film. When removing the film after construction, the surface should be washed, and special stainless steel tools should be used. When cleaning common tools with steel, it should be cleaned to prevent iron filings from sticking.

Care should be taken not to allow the highly corrosive magnetic and cleaning drugs to contact the stainless steel surface. If it is in contact, it should be washed immediately. After the construction, apply neutral detergent or water to wash the cement, powder and other things on the surface.

Please check some stainless steel products from Haihao group,we provide professional service and products,we work with many international projects.If you have related inquiry,please contact us :sales@haihaogroup.com