Solid solution characteristics of stainless steel pipe fittings

The solid solution process of stainless steel pipe fitting has a great influence on the corrosion resistance and appearance brightness of stainless steel, and plays a decisive role in the processing performance of stainless steel. Therefore, the heat treatment process of stainless steel is very important in the production of stainless steel pipe fittings.

Stainless steel is a special kind of steel. Because of the existence of alloying elements such as nickel and chromium, its heat treatment has different characteristics from that of ordinary steel.

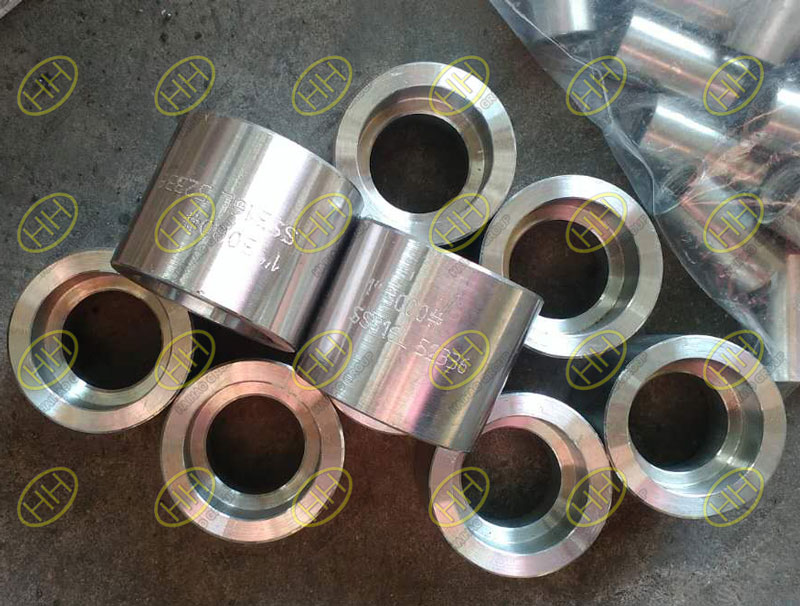

ASTM A182 F316L Socket Weld Couplings

1. The thermal conductivity of stainless steel is low, which is only 27% of that of carbon steel at room temperature. With the increase of heating temperature, the thermal conductivity of stainless steel decreases gradually. Therefore, when stainless steel is heated at low temperature, the heating process should be carried out slowly.

2.Stainless steel can inhibit carbide formation by solution heating to about 1100 ℃, then rapidly cool to room temperature, so that carbon reaches supersaturation state, which can greatly improve the corrosion resistance of stainless steel.

ASME B16.9 A403 lap joint stub ends finished in Haihao Group

3.Gas protection (hydrogen) is used in the solid solution process to avoid the formation of viscous iron oxide on the surface of stainless steel, reduce the brightness of the surface of stainless steel, and improve the appearance of the reputation.

This three elements of sold solution for stainless steel pipe fittings

- Solution temperature

- Solution time.

- Solution speed and heat preservation

In solid solution production, the solid solution of stainless steel pipe fitting needs to be heated, insulated and time cooled, and the whole process takes about 40 minutes.