What is 3PE three-layer protective layer?

3PE anti-corrosion steel pipe polyethylene three-layer structural protective layer, also known as three-layer PE, is an advanced anti-corrosion skill introduced from abroad in recent years. But do you know 3 layers of protection? Today we will take a closer look at the 3PE three-layer protective layer.(The definition and advantage of 3PE)

The full name of the 3PE anticorrosive layer is a sintered epoxy / extruded polyethylene structural protective layer, which is mainly composed of the following three layers. The first layer of sintered epoxy, the middle layer of adhesive and the last layer of extruded polyethylene. The total thickness of the protective layer is not less than 1.8mm and not more than 3.7mm.

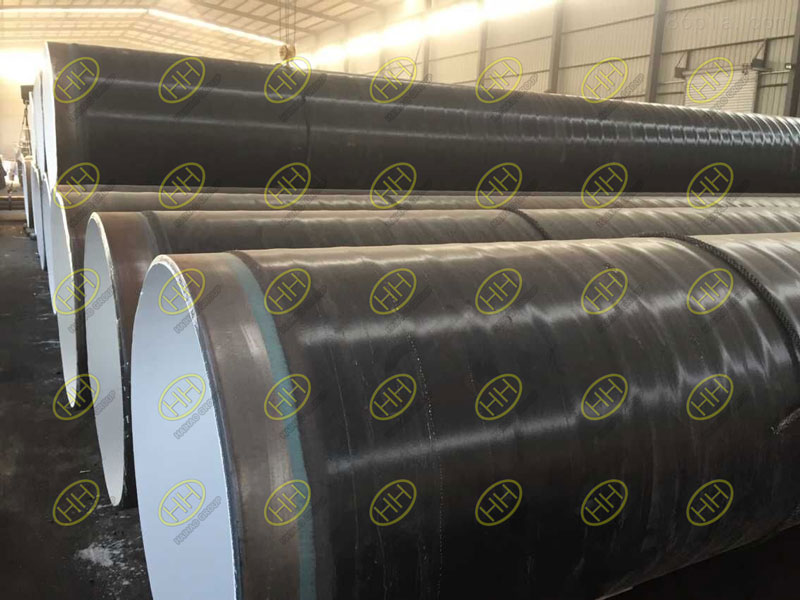

3PE anti corrosion coated steel pipes

In the three-layer structure, the main function of the sintered epoxy powder coating is to form a continuous coating film, which is directly bonded to the surface of the steel pipe, and has good chemical resistance and anti-cathode peeling performance. The reactive group reacts to form a chemical bond, ensuring that the overall anticorrosive layer has good adhesion at higher temperatures.

The intermediate layer is usually a copolymer binder, whose main component is polyolefin. Currently, a vinyl copolymer adhesive is widely used. The functional group of the polar part of the copolymer adhesive and the epoxy group of the sintered epoxy powder coating can react to form hydrogen bonds or chemical bonds, so that the middle layer and the bottom layer form a good bond; the non-polar ethylene part and the top layer Polyethylene has a good affinity, so the middle layer and the surface layer also have good adhesion properties.

The main function of the polyethylene surface layer is to provide mechanical protection and anticorrosion, which has the same function as the traditional two-layer polyethylene anticorrosion layer.

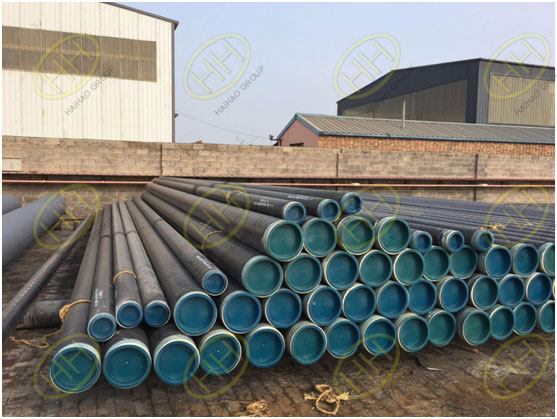

3PE anti corrosion coating steel pipes

In the manufacturing process of 3PE anti-corrosion steel pipe, the three materials will be mixed and integrated in the way of winding and covering of the original mold, so that the steel pipe and it can be combined into an excellent anti-corrosion coating to achieve the anti-corrosion effect of the steel pipe.

This anticorrosive coating manufacturing technology is a clever combination of 2PE anticorrosive coating in Europe and epoxy powder anticorrosive steel pipe coating in North America. It has been used in the world for more than ten years, so its effect is very good. Three PE anticorrosive coating has the characteristics of both high impermeability and high mechanical properties of epoxy resin and polyethylene materials. At present, it is the globally recognized anticorrosive coating method with the best application effect and performance, so it is widely used in many projects.

3PE anticorrosion insulated steel pipe

As a professional steel pipe supplier, Hebei haihao group has a history of more than 30 years. Our company has specially developed flame-retardant and antistatic polyethylene pipes, which are suitable for specific places such as flammable and explosiveI.

If you trust us,please feel free to contact us.Email:sales@haihaogroup.com