ASME B16.47 Class 150 Series A Flange (Weld Neck and Blind Flange)

In recent years, we’ve seen more pipeline projects moving toward larger diameters, especially in petrochemical and offshore systems. That’s where ASME B16.47 Series A weld neck and blind flanges come into play. These flanges are engineered to handle high-pressure environments while ensuring reliable sealing and long-term structural integrity.

At Haihao Group, I’ve personally overseen multiple production batches of Series A flanges, ranging from 26-inch to 60-inch sizes, for customers in the Middle East, Southeast Asia, and Europe.

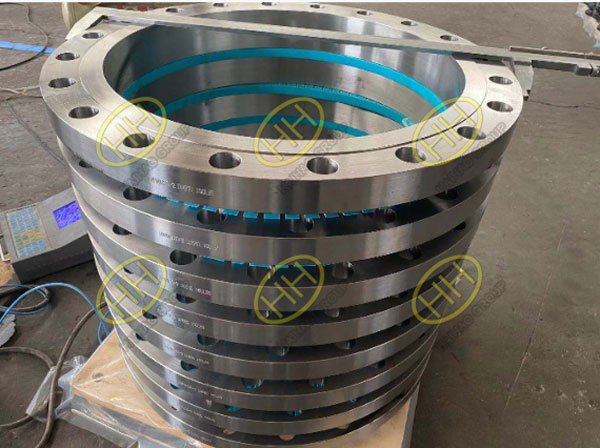

ASME B16.47 Series A weld neck flanges machined and inspected in workshop

What Sets Series A Flanges Apart

ASME B16.47 defines two flange series: A and B. Series A flanges are often selected for their thicker profiles and higher bolt loads, making them suitable for critical process piping. Compared to Series B, Series A flanges generally have:

- Larger bolt circle diameters

- Fewer bolt holes per flange size

- Heavier construction for added safety margin

When clients specify Class 150 Series A weld neck or blind flanges, they typically prioritize ease of alignment and proven performance under pressure cycles.

Key Features of Class 150 Series A Flanges

Nominal Pipe Size Range:Covers flanges for pipe sizes from NPS 26 inches to 60 inches.

Pressure Class:Rated for Class 150, suitable for systems operating at lower pressures.

Design and Structure:

Thicker and Heavier than Series B flanges, providing enhanced strength and better load-handling capacity.

Larger bolt circle diameter and bolt hole sizes compared to Series B, offering superior mechanical integrity.

Materials:Commonly manufactured from carbon steel (A105), stainless steel, or alloy steel, ensuring durability and adaptability to various operating conditions.

Gasket Compatibility:Designed with a raised face (RF) or flat face (FF) to accommodate standard gaskets for a secure seal.

Applications:Preferred for pipelines where safety, reliability, and strength are critical, especially in high-stress environments.

Dimensional Specifications

Key dimensions for a Class 150 Series A flange include:

- Outer Diameter (OD): Larger than Series B flanges for improved structural strength.

- Bolt Circle Diameter: Accommodates more bolts for enhanced connection stability.

- Flange Thickness: Heavier construction ensures better performance under stress.

- Bolt Hole Count: Higher number of bolt holes for a stronger, leak-proof connection.

Dimension of ASME B16.47 Class 150 Series A Flange:

Dimensions of ASME B16.47 Class 150 Series A Flanges

| Nominal Pipe Size | O.D. of flange | Minimum Thickness of Flange,tf[Note(1)] | Length Through Hub | Diam. of Hub | Hub Diam. Top | Raised Face Diam. | Drilling | Diam. of Bolt,in. | Minimum Fillet Radius | |||

| O | WNF | Blind | Y | X[Note(2)] | A | R | Diam. of Bolt Circle | No. of Bolt Holes | Diam. of Bolt Hole,in. | r1 | ||

| 26 | 870 | 66.7 | 66.7 | 119 | 676 | 660.4 | 749 | 806.4 | 24 | 1 ⅜ | 1 ¼ | 10 |

| 28 | 925 | 69.9 | 69.9 | 124 | 727 | 711.2 | 800 | 863.6 | 28 | 1 ⅜ | 1 ¼ | 11 |

| 30 | 985 | 73.1 | 73.1 | 135 | 781 | 762.0 | 857 | 914.4 | 28 | 1 ⅜ | 1 ¼ | 11 |

| 32 | 1060 | 79.4 | 79.4 | 143 | 832 | 812.8 | 914 | 977.9 | 28 | 1 ⅝ | 1 ½ | 11 |

| 34 | 1110 | 81.0 | 81.0 | 148 | 883 | 863.6 | 965 | 1028.7 | 32 | 1 ⅝ | 1 ½ | 13 |

| 36 | 1170 | 88.9 | 88.9 | 156 | 933 | 914.4 | 1022 | 1085.8 | 32 | 1 ⅝ | 1 ½ | 13 |

| 38 | 1240 | 85.8 | 85.8 | 156 | 991 | 965.2 | 1073 | 1149.4 | 32 | 1 ⅝ | 1 ½ | 13 |

| 40 | 1290 | 88.9 | 88.9 | 162 | 1041 | 1016.0 | 1124 | 1200.2 | 36 | 1 ⅝ | 1 ½ | 13 |

| 42 | 1345 | 95.3 | 95.3 | 170 | 1092 | 1066.8 | 1194 | 1257.3 | 36 | 1 ⅝ | 1 ½ | 13 |

| 44 | 1405 | 100.1 | 100.1 | 176 | 1143 | 1117.6 | 1245 | 1314.4 | 40 | 1 ⅝ | 1 ½ | 13 |

| 46 | 1455 | 101.6 | 101.6 | 184 | 1197 | 1168.4 | 1295 | 1365.2 | 40 | 1 ⅝ | 1 ½ | 13 |

| 48 | 1510 | 106.4 | 106.4 | 191 | 1248 | 1219.2 | 1359 | 1422.4 | 44 | 1 ⅝ | 1 ½ | 13 |

| 50 | 1570 | 109.6 | 109.6 | 202 | 1302 | 1270.0 | 1410 | 1479.6 | 44 | 1 ⅞ | 1 ¾ | 13 |

| 52 | 1625 | 114.3 | 114.3 | 208 | 1353 | 1320.8 | 1461 | 1536.7 | 44 | 1 ⅞ | 1 ¾ | 13 |

| 54 | 1685 | 119.1 | 119.1 | 214 | 1403 | 1371.6 | 1511 | 1593.8 | 44 | 1 ⅞ | 1 ¾ | 13 |

| 56 | 1745 | 122.3 | 122.3 | 227 | 1457 | 1422.4 | 1575 | 1651.0 | 48 | 1 ⅞ | 1 ¾ | 13 |

| 58 | 1805 | 127.0 | 127.0 | 233 | 1508 | 1473.2 | 1626 | 1708.2 | 48 | 1 ⅞ | 1 ¾ | 13 |

| 60 | 1855 | 130.2 | 130.2 | 238 | 1559 | 1524.0 | 1676 | 1759.0 | 52 | 1 ⅞ | 1 ¾ | 13 |

GENERAL NOTES:

(a)Dimensions are in millimeters.

(b)Blind flanges may be made with or without hubs at the manufacturer’s option.

NOTES:

(1)The minimum flange thickness does not include the raised face thickness.

(2)This dimension is for the large end of hub,which may be straight or tapered.

Large diameter Series A flanges packed in plywood crates ready for shipment

Production and Machining Process

Our typical workflow for Series A weld neck and blind flanges includes:

1️⃣ Raw Forging:

We start with fully-killed carbon steel or alloy steel forgings. For carbon grades, A105 and A350 LF2 are common; for higher temperature ratings, F304/316 or F11 materials are used.

2️⃣ Rough Machining:

Initial turning is done to bring the flange close to final dimensions.

3️⃣ Heat Treatment:

Depending on material grade, normalizing or tempering is applied to achieve target mechanical properties.

4️⃣ Finish Machining:

Facing to achieve a smooth or serrated finish on the gasket seating surface.

Drilling bolt holes according to ASME B16.47 tolerances.

Boring the hub for weld neck types.

5️⃣ Inspection:

Dimensional checks, ultrasonic testing (UT), and magnetic particle inspection (MT) are performed. Clients often request a third-party witness (e.g., Lloyd’s Register, SGS).

6️⃣ Surface Protection:

After inspection, machined surfaces are coated with rust preventive oil, and flange faces are protected by plastic covers.

7️⃣ Marking and Packing:

Each flange is marked with size, class, material grade, heat number, and standard. Final packing uses export-grade plywood crates with clear labeling.

Haihao Group can provide a variety ASME B16.47 standard flange,as follows:

- ASME B16.47 Class 150 Series A Flange

- ASME B16.47 Class 300 Series A Flange

- ASME B16.47 Class 400 Series A Flange

- ASME B16.47 Class 600 Series A Flange

- ASME B16.47 Class 900 Series A Flange

- ASME B16.47 Class 75 Series B Flange

- ASME B16.47 Class 150 Series B Flange

- ASME B16.47 Class 300 Series B Flange

- ASME B16.47 Class 400 Series B Flange

- ASME B16.47 Class 600 Series B Flange

- ASME B16.47 Class 900 Series B Flange

Applications of Class 150 Series A Flanges

Class 150 Series A flanges are used in a variety of industrial applications, including:

- Oil and Gas Pipelines: Ideal for transporting crude oil and natural gas at lower pressures.

- Petrochemical Plants: Used in systems requiring secure and reliable connections.

- Water Treatment Systems: Suitable for large-scale water distribution projects.

- Power Plants: Used in lower-pressure steam and cooling water systems.

Advantages of ASME B16.47 Class 150 Series A Flanges

- Strength and Durability: Robust design ensures excellent performance in demanding conditions.

- Standardized Dimensions: Allows for easy integration into existing pipeline systems.

- Leak-Proof Connections: Larger bolt patterns and enhanced construction minimize the risk of leakage.

- Versatility: Compatible with various piping materials and gasket types.

Why Choose Haihao Group for ASME B16.47 Class 150 Series A Flanges?

At Haihao Group, we manufacture and supply high-quality ASME B16.47 Class 150 Series A flanges designed to meet the most stringent industry requirements.

- Precision Engineering: Our flanges are made to exact ASME specifications for flawless performance.

- Premium Materials: Produced from top-grade materials like carbon steel A105 for strength and reliability.

- Comprehensive Testing: Each flange undergoes rigorous quality checks to ensure compliance and durability.

- Global Reach: With extensive shipping capabilities, we deliver products to customers worldwide.

Serrated face finish on ASME B16.47 Class 150 weld neck flange

Recent Project Highlight

Earlier this year, we supplied over 20 pieces of B16.47 A CL150 A105 RF weld neck flanges for oil industry in Saudi Arabia. The project required full EN10204 3.2 certification and supplementary impact testing at -46°C due to low ambient conditions.

To meet the schedule, we arranged parallel machining on multiple CNC lathes and coordinated with the client’s inspector to approve each batch progressively. The shipment was completed within one weeks, including all documentation and compliance checks.

Contact Us

For more details about ASME B16.47 Class 150 Series A flanges, or to request a quote, reach out to Haihao Group today. We are committed to providing the best solutions for your pipeline needs! Email: sales@haihaogroup.com