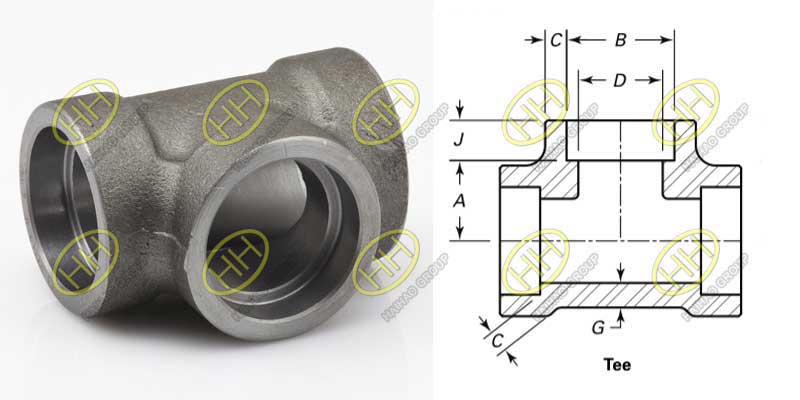

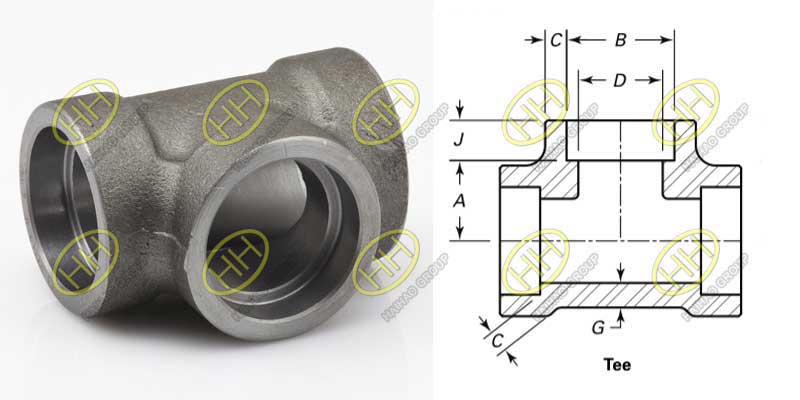

ASME B16.11 Socket Welding Tee

The ASME B16.11 standard covers the specifications for forged steel fittings, including socket welding fittings and threaded fittings.The ASME B16.11 socket welding tee stands as a testament to quality and reliability. This forged steel fitting is crafted with precision to provide a seamless branch connection at a right angle (90 degrees) to the main pipe run. Its design, in adherence to the ASME B16.11 standard, ensures a robust and durable solution for diverse industrial applications.

ANSI ASME B16.11 socket weld equal tee

Our ASME B16.11 socket welding tees find applications across a spectrum of industries, including oil and gas, chemical, petrochemical, and power generation. Whether you require a branch connection in a high-pressure system or demand precision in your piping layout, these tees deliver.

We manufacture socket welding tees according to ASME B16.11 standard in the nominal pipe size ⅛ through 4. The materials can be carbon steel,stainless steel,alloy steel and so on.The dimensions of socket welding tees according to ASME B16.11 standard as follows:

ASME B16.11 Socket Welding Tees Dimensions:

ASME B6.11 Socket Welding Tee

| Nominal Pipe Size | Socker Bore Dia., B | Bore Diameter of Fittings, D | Socket Wall Thickness, C [Note (1)] | Body Wall,G | Socket Depth,J | Center-to-Bottom of Socket, A | ||||||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | Tol.,± | ||||||||||

| Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Avg. | Min. | Avg. | Min. | Avg. | Min. | Min. | Min. | Min. | Min. | |||||

| ⅛ | 11.2 | 10.8 | 7.6 | 6.1 | 4.8 | 3.2 | … | … | 3.18 | 3.18 | 3.96 | 3.43 | … | … | 2.41 | 3.15 | … | 9.5 | 11.0 | 11.0 | … | 1.0 |

| ¼ | 14.6 | 14.2 | 10.0 | 8.5 | 7.1 | 5.6 | … | … | 3.78 | 3.30 | 4.60 | 4.01 | … | … | 3.02 | 3.68 | … | 9.5 | 11.0 | 13.5 | … | 1.0 |

| ⅜ | 18.0 | 17.6 | 13.3 | 11.8 | 9.9 | 8.4 | … | … | 4.01 | 3.50 | 5.03 | 4.37 | … | … | 3.20 | 4.01 | … | 9.5 | 13.5 | 15.5 | … | 1.5 |

| ½ | 22.2 | 21.8 | 16.6 | 15.0 | 12.5 | 11.0 | 7.2 | 5.6 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 3.73 | 4.78 | 7.47 | 9.5 | 15.5 | 19.0 | 25.5 | 1.5 |

| ¾ | 27.6 | 27.2 | 21.7 | 20.2 | 16.3 | 14.8 | 11.8 | 10.3 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 3.91 | 5.56 | 7.82 | 12.5 | 19.0 | 22.5 | 28.5 | 1.5 |

| 1 | 34.3 | 33.9 | 27.4 | 25.9 | 21.5 | 19.9 | 16.0 | 14.4 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 4.55 | 6.35 | 9.09 | 12.5 | 22.5 | 27.0 | 32.0 | 2.0 |

| 1¼ | 43.1 | 42.7 | 35.8 | 34.3 | 30.2 | 28.7 | 23.5 | 22.0 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 4.85 | 6.35 | 9.70 | 12.5 | 27.0 | 32.0 | 35.0 | 2.0 |

| 1½ | 49.2 | 48.8 | 41.6 | 40.1 | 34.7 | 33.2 | 28.7 | 27.2 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 10.15 | 12.5 | 32.0 | 38.0 | 38.0 | 2.0 |

| 2 | 61.7 | 61.2 | 53.3 | 51.7 | 43.6 | 42.1 | 38.9 | 37.4 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 5.54 | 8.74 | 11.07 | 16.0 | 38.0 | 41.0 | 54.0 | 2.0 |

| 2½ | 74.4 | 73.9 | 64.2 | 61.2 | … | … | … | … | 8.76 | 7.67 | … | … | … | … | 7.01 | … | … | 16.0 | 41.0 | … | … | 2.5 |

| 3 | 90.3 | 89.8 | 79.4 | 76.4 | … | … | … | … | 9.52 | 8.30 | … | … | … | … | 7.62 | … | … | 16.0 | 57.0 | … | … | 2.5 |

| 4 | 115.7 | 115.2 | 103.8 | 100.7 | … | … | … | … | 10.69 | 9.35 | … | … | … | … | 8.56 | … | … | 19.0 | 66.5 | … | … | 2.5 |

General note: Dimensions are in millimeters.

Note (1): Average of socket wall thickness around periphery shall not be less than listed values.The minimum values are permitted in localized areas.

ASME B6.11 Socket Welding Tee

| Nominal Pipe Size | Socker Bore Dia., B | Bore Diameter of Fittings, D | Socket Wall Thickness, C [Note (1)] | Body Wall,G | Socket Depth,J | Center-to-Bottom of Socket, A | ||||||||||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | Tol.,± | ||||||||||

| Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Avg. | Min. | Avg. | Min. | Avg. | Min. | Min. | Min. | Min. | Min. | |||||

| ⅛ | 0.440 | 0.420 | 0.299 | 0.239 | 0.189 | 0.126 | … | … | 0.125 | 0.125 | 0.156 | 0.135 | … | … | 0.095 | 0.124 | … | 0.38 | 0.44 | 0.44 | … | 0.03 |

| ¼ | 0.575 | 0.555 | 0.394 | 0.334 | 0.280 | 0.220 | … | … | 0.149 | 0.130 | 0.181 | 0.158 | … | … | 0.119 | 0.145 | … | 0.38 | 0.44 | 0.53 | … | 0.03 |

| ⅜ | 0.710 | 0.690 | 0.523 | 0.463 | 0.389 | 0.329 | … | … | 0.158 | 0.138 | 0.198 | 0.172 | … | … | 0.126 | 0.158 | … | 0.38 | 0.53 | 0.62 | … | 0.06 |

| ½ | 0.875 | 0.855 | 0.652 | 0.592 | 0.494 | 0.434 | 0.282 | 0.222 | 0.184 | 0.161 | 0.235 | 0.204 | 0.368 | 0.322 | 0.147 | 0.188 | 0.294 | 0.38 | 0.62 | 0.75 | 1.00 | 0.06 |

| ¾ | 1.085 | 1.065 | 0.854 | 0.794 | 0.642 | 0.582 | 0.464 | 0.404 | 0.193 | 0.168 | 0.274 | 0.238 | 0.385 | 0.337 | 0.154 | 0.219 | 0.308 | 0.50 | 0.75 | 0.88 | 1.12 | 0.06 |

| 1 | 1.350 | 1.330 | 1.079 | 1.019 | 0.845 | 0.785 | 0.629 | 0.569 | 0.224 | 0.196 | 0.312 | 0.273 | 0.448 | 0.392 | 0.179 | 0.250 | 0.358 | 0.50 | 0.88 | 1.06 | 1.25 | 0.08 |

| 1¼ | 1.695 | 1.675 | 1.410 | 1.350 | 1.190 | 1.130 | 0.926 | 0.866 | 0.239 | 0.208 | 0.312 | 0.273 | 0.478 | 0.418 | 0.191 | 0.250 | 0.382 | 0.50 | 1.06 | 1.25 | 1.38 | 0.08 |

| 1½ | 1.935 | 1.915 | 1.640 | 1.580 | 1.368 | 1.308 | 1.130 | 1.070 | 0.250 | 0.218 | 0.351 | 0.307 | 0.500 | 0.438 | 0.200 | 0.281 | 0.400 | 0.50 | 1.25 | 1.50 | 1.50 | 0.08 |

| 2 | 2.426 | 2.406 | 2.097 | 2.037 | 1.717 | 1.657 | 1.533 | 1.473 | 0.273 | 0.238 | 0.430 | 0.374 | 0.545 | 0.477 | 0.218 | 0.344 | 0.436 | 0.62 | 1.50 | 1.62 | 2.12 | 0.08 |

| 2½ | 2.931 | 2.906 | 2.529 | 2.409 | … | … | … | … | 0.345 | 0.302 | … | … | … | … | 0.276 | … | … | 0.62 | 1.62 | … | … | 0.10 |

| 3 | 3.560 | 3.535 | 3.128 | 3.008 | … | … | … | … | 0.375 | 0.327 | … | … | … | … | 0.300 | … | … | 0.62 | 2.25 | … | … | 0.10 |

| 4 | 4.570 | 4.545 | 4.086 | 3.966 | … | … | … | … | 0.421 | 0.368 | … | … | … | … | 0.337 | … | … | 0.75 | 2.62 | … | … | 0.10 |

General note: Dimensions are in inches.

Note (1): Average of socket wall thickness around periphery shall not be less than listed values.The minimum values are permitted in localized areas.

Meanwhile,we manufacture & supply different types of socket welding pipe fittings according to ASME B16.11 standard as follows:

- ASME B16.11 socket welding 45° elbows,socket welding 90° elbows

- ASME B16.11 socket welding tees

- ASME B16.11 socket welding crosses

- ASME B16.11 socket welding bosses

- ASME B16.11 socket welding caps

- ASME B16.11 socket welding couplet

- ASME B16.11 socket welding full coupling,socket welding half coupling

Haihao Group manufacture & supply & export pipeline products more than 30 years,which contain butt welding pipe fittings(elbows,tees,reducers,caps,bends,crosses,etc),forged pipe fittings(socket weld/threaded elbows, tees, reducers, crosses, couplings, union, outlet, nipple, etc),steel pipes(seamless steel pipes, SAW/ERW steel pipes, casing and tubing pipes,etc) and forged flanges(weld neck flange, slip on flange, blind flange, lap joint flange, plate flange, threaded flange, socket weld flange, orifice flange, spectacle blind flange, weld overlay cladding flange,etc).We supply the products in different standards such as ANSI/ASME, ASTM, BS, EN, JIS, GOST, ISO, MSS, etc.If you want to know more about our pipeline products,please email us:sales@haihaogroup.com