ASME B16.11 Socket Welding Couplet

ASME B16.11 socket welding couplet is a welded branch plate that is welded to the main pipe and connected to the branch pipe, either by welding or threaded connection. It is considered the most popular in the group, and is often classified as a butt-welding connection (BW butt-welding). This classification refers to the beveled outlet that is welded during installation to the branch pipe. It is highly suitable for replacing tees with reinforced connections on 90-degree branch pipes, as this connection protects the branch pipe by reducing stress concentrations caused by the shape and size of the branch pipe. The beveled end allows for easy installation on previously cut main pipes and branch pipes through butt-welding, with the internal or nominal diameter of the branch pipe usually being less than or equal to the diameter of the welded branch plate. The main application is commonly found in hot well and instrument connections.

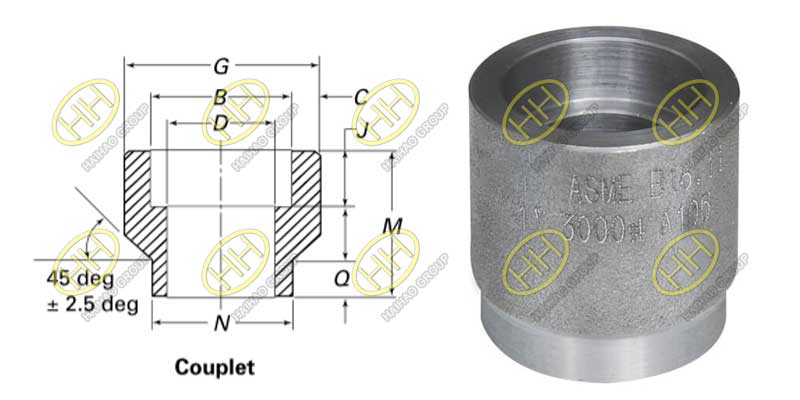

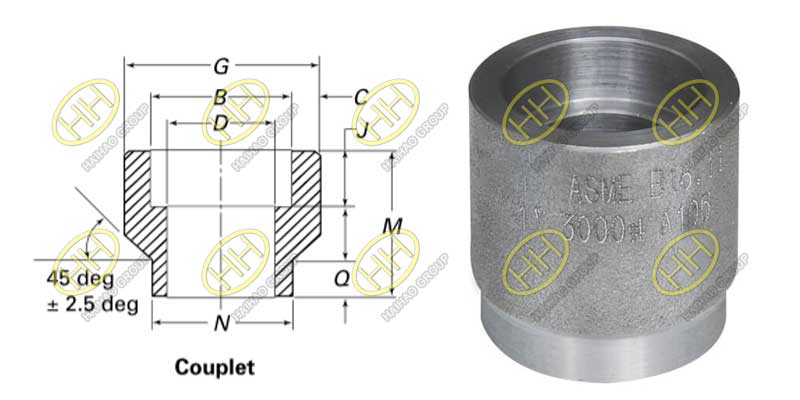

ASME B16.11 Socket Welding Couplet Dimensions:

ASME B16.11 socket welding couplet

| Nominal Pipe Size | Socker Bore Dia., B | Bore Diameter of Fittings, D | Socket Wall Thickness, C [Note (1)] | Outside Dia. Couplet, G | Socket Depth,J | End-to-End Couplet, M | Weld Ring Diameter, N | Weld Ring Length, Q | ||||||||||||

| 3000 | 6000 | 3000 | 6000 | |||||||||||||||||

| Max. | Min. | Max. | Min. | Max. | Min. | Avg. | Min. | Avg. | Min. | 3000 | 6000 | Tol. | Min. | Tol.,± | Tol. | 3000/6000 | Tol.,± | |||

| ¼ | 14.6 | 14.2 | 10.0 | 8.5 | 7.1 | 5.6 | 3.78 | 3.30 | 4.60 | 4.01 | 23.8 | 25.4 | ±1.5/−0.0 | 9.5 | 30.2 | ±0.8/−0.0 | 17.5 | ±1.5/−0.0 | 9.5 | 0.8 |

| ⅜ | 18.0 | 17.6 | 13.3 | 11.8 | 9.9 | 8.4 | 4.01 | 3.50 | 5.03 | 4.37 | 27.0 | 31.8 | ±1.5/−0.0 | 9.5 | 30.2 | ±0.8/−0.0 | 20.7 | ±1.5/−0.0 | 9.5 | 0.8 |

| ½ | 22.2 | 21.8 | 16.6 | 15.0 | 12.5 | 11.0 | 4.67 | 4.09 | 5.97 | 5.18 | 33.4 | 38.1 | ±1.5/−0.0 | 9.5 | 33.4 | ±0.8/−0.0 | 23.8 | ±1.5/−0.0 | 9.5 | 0.8 |

| ¾ | 27.6 | 27.2 | 21.7 | 20.2 | 16.3 | 14.8 | 4.90 | 4.27 | 6.96 | 6.04 | 38.1 | 44.5 | ±1.5/−0.0 | 12.5 | 34.9 | ±0.8/−0.0 | 27.0 | ±1.5/−0.0 | 9.5 | 0.8 |

| 1 | 34.3 | 33.9 | 27.4 | 25.9 | 21.5 | 19.9 | 5.69 | 4.98 | 7.92 | 6.93 | 46.1 | 57.2 | ±1.5/−0.0 | 12.5 | 42.9 | ±0.8/−0.0 | 33.4 | ±1.5/−0.0 | 9.5 | 0.8 |

| 1¼ | 43.1 | 42.7 | 35.8 | 34.3 | 30.2 | 28.7 | 6.07 | 5.28 | 7.92 | 6.93 | 55.6 | 63.5 | ±1.5/−0.0 | 12.5 | 42.9 | ±0.8/−0.0 | 33.4 | ±1.5/−0.0 | 9.5 | 0.8 |

| 1½ | 49.2 | 48.8 | 41.6 | 40.1 | 34.7 | 33.2 | 6.35 | 5.54 | 8.92 | 7.80 | 63.5 | 76.2 | ±1.5/−0.0 | 12.5 | 50.8 | ±0.8/−0.0 | 49.2 | ±1.5/−0.0 | 9.5 | 0.8 |

| 2 | 61.7 | 61.2 | 53.3 | 51.7 | 43.6 | 42.1 | 6.93 | 6.04 | 10.92 | 9.50 | 79.4 | 92.1 | ±1.5/−0.0 | 16.0 | 57.2 | ±1.5/−0.0 | 61.9 | ±1.5/−0.0 | 9.5 | 0.8 |

| 2½ | 74.4 | 73.9 | 64.2 | 61.2 | … | … | 8.76 | 7.67 | … | … | 92.1 | 108.0 | ±1.5/−0.0 | 16.0 | 63.5 | ±1.5/−0.0 | 73.0 | ±1.5/−0.0 | 9.5 | 0.8 |

| 3 | 90.3 | 89.8 | 79.4 | 76.4 | … | … | 9.52 | 8.30 | … | … | 111.1 | 127.0 | ±1.5/−0.0 | 16.0 | 69.9 | ±1.5/−0.0 | 88.9 | ±1.5/−0.0 | 9.5 | 0.8 |

| 4 | 115.7 | 115.2 | 103.8 | 100.7 | … | … | 10.69 | 9.35 | … | … | 141.3 | 158.8 | ±1.5/−0.0 | 19.0 | 76.2 | ±1.5/−0.0 | 114.3 | ±1.5/−0.0 | 9.5 | 0.8 |

General note: Dimensions are in millimeters.

Note (1): Average of socket wall thickness around periphery shall not be less than listed values.The minimum values are permitted in localized areas.

ASME B16.11 socket welding couplet

| Nominal Pipe Size | Socker Bore Dia., B | Bore Diameter of Fittings, D | Socket Wall Thickness, C [Note (1)] | Outside Dia. Couplet, G | Socket Depth,J | Laying Length,F | End to End Couplet, M | Weld Ring Diameter, N | Weld Ring Length,Q | |||||||||||||

| 3000 | 6000 | 3000 | 6000 | |||||||||||||||||||

| Max. | Min. | Max. | Min. | Max. | Min. | Avg. | Min. | Avg. | Min. | 3000 | 6000 | Tol. | Min. | Tol.,± | Tol. | Tol. | 3000/6000 | Tol.,± | ||||

| ¼ | 0.575 | 0.555 | 0.394 | 0.334 | 0.280 | 0.220 | 0.149 | 0.130 | 0.181 | 0.158 | 0.94 | 1.00 | ±0.06/-0.00 | 0.38 | 0.62 | 0.03 | 1.19 | ±0.03/-0.00 | 0.69 | ±0.06/-0.00 | 0.38 | 0.03 |

| ⅜ | 0.710 | 0.690 | 0.523 | 0.463 | 0.389 | 0.329 | 0.158 | 0.138 | 0.198 | 0.172 | 1.06 | 1.25 | ±0.06/-0.00 | 0.38 | 0.69 | 0.06 | 1.19 | ±0.03/-0.00 | 0.81 | ±0.06/-0.00 | 0.38 | 0.03 |

| ½ | 0.875 | 0.855 | 0.652 | 0.592 | 0.494 | 0.434 | 0.184 | 0.161 | 0.235 | 0.204 | 1.31 | 1.50 | ±0.06/-0.00 | 0.38 | 0.88 | 0.06 | 1.31 | ±0.03/-0.00 | 0.94 | ±0.06/-0.00 | 0.38 | 0.03 |

| ¾ | 1.085 | 1.065 | 0.854 | 0.794 | 0.642 | 0.582 | 0.193 | 0.168 | 0.274 | 0.238 | 1.50 | 1.75 | ±0.06/-0.00 | 0.50 | 0.94 | 0.06 | 1.38 | ±0.03/-0.00 | 1.06 | ±0.06/-0.00 | 0.38 | 0.03 |

| 1 | 1.350 | 1.330 | 1.079 | 1.019 | 0.845 | 0.785 | 0.224 | 0.196 | 0.312 | 0.273 | 1.81 | 2.25 | ±0.06/-0.00 | 0.50 | 1.12 | 0.08 | 1.69 | ±0.03/-0.00 | 1.31 | ±0.06/-0.00 | 0.38 | 0.03 |

| 1¼ | 1.695 | 1.675 | 1.410 | 1.350 | 1.190 | 1.130 | 0.239 | 0.208 | 0.312 | 0.273 | 2.19 | 2.50 | ±0.06/-0.00 | 0.50 | 1.19 | 0.08 | 1.88 | ±0.03/-0.00 | 1.69 | ±0.06/-0.00 | 0.38 | 0.03 |

| 1½ | 1.935 | 1.915 | 1.640 | 1.580 | 1.368 | 1.308 | 0.250 | 0.218 | 0.351 | 0.307 | 2.50 | 3.00 | ±0.06/-0.00 | 0.50 | 1.25 | 0.08 | 2.00 | ±0.03/-0.00 | 1.94 | ±0.06/-0.00 | 0.38 | 0.03 |

| 2 | 2.426 | 2.406 | 2.097 | 2.037 | 1.717 | 1.657 | 0.273 | 0.238 | 0.430 | 0.374 | 3.13 | 3.63 | ±0.06/-0.00 | 0.62 | 1.62 | 0.08 | 2.25 | ±0.06/-0.00 | 2.44 | ±0.06/-0.00 | 0.38 | 0.03 |

| 2½ | 2.931 | 2.906 | 2.529 | 2.409 | … | … | 0.345 | 0.302 | … | … | 3.63 | 4.25 | ±0.06/-0.00 | 0.62 | 1.69 | 0.10 | 2.50 | ±0.06/-0.00 | 2.88 | ±0.06/-0.00 | 0.38 | 0.03 |

| 3 | 3.560 | 3.535 | 3.128 | 3.008 | … | … | 0.375 | 0.327 | … | … | 4.38 | 5.00 | ±0.06/-0.00 | 0.62 | 1.75 | 0.10 | 2.75 | ±0.06/-0.00 | 3.50 | ±0.06/-0.00 | 0.38 | 0.03 |

| 4 | 4.570 | 4.545 | 4.086 | 3.966 | … | … | 0.421 | 0.368 | … | … | 5.56 | 6.25 | ±0.06/-0.00 | 0.75 | 1.88 | 0.10 | 3.00 | ±0.06/-0.00 | 4.50 | ±0.06/-0.00 | 0.38 | 0.03 |

General note: Dimensions are in inches.

Note (1): Average of socket wall thickness around periphery shall not be less than listed values.The minimum values are permitted in localized areas.

Meanwhile,we manufacture & supply different types of socket welding pipe fittings according to ASME B16.11 standard as follows:

- ASME B16.11 socket welding 45° elbows,socket welding 90° elbows

- ASME B16.11 socket welding tees

- ASME B16.11 socket welding crosses

- ASME B16.11 socket welding bosses

- ASME B16.11 socket welding caps

- ASME B16.11 socket welding couplet

- ASME B16.11 socket welding full coupling,socket welding half coupling

Haihao Group manufacture & supply & export pipeline products more than 30 years,which contain butt welding pipe fittings (elbows, tees, reducers, caps, bends, crosses, etc), forged pipe fittings (socket weld/threaded elbows, tees, reducers, crosses, couplings, union, outlet, nipple, etc), steel pipes(seamless steel pipes, SAW/ERW steel pipes, casing and tubing pipes, etc) and forged flanges(weld neck flange, slip on flange, blind flange, lap joint flange, plate flange, threaded flange, socket weld flange, orifice flange, spectacle blind flange, weld overlay cladding flange,etc).We supply the products in different standards such as ANSI/ASME, ASTM, BS, EN, JIS, GOST, ISO, MSS, etc.If you want to know more about our pipeline products,please email us:sales@haihaogroup.com