ASME B16.11 Socket Welding Caps

ASME B16.11 socket welding caps are forged fittings designed for use in high-pressure piping systems. The primary function of a socket welding cap is to seal the end of a pipe. It provides a rounded closure for the pipe, preventing the flow of fluids or gases.Socket welding caps are used in various piping systems to connect sections of pipe or to modify the flow of fluid in a system. They are available in a range of sizes, ranging from small diameters to large diameters, and are typically made of steel or stainless steel.

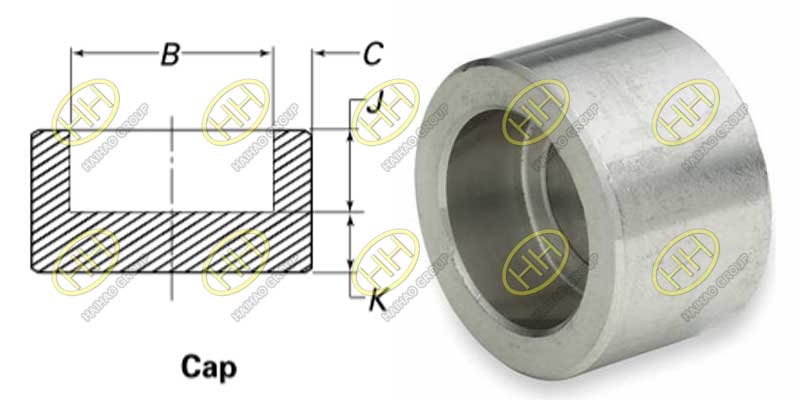

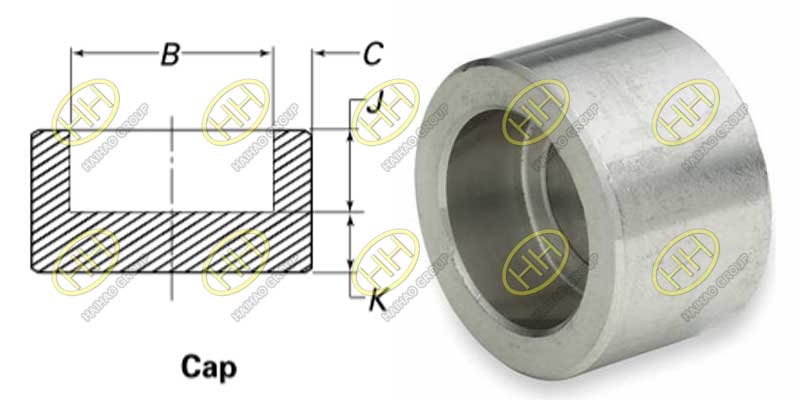

Haihao Group manufacture socket welding caps according to ASME B16.11 standard in the nominal pipe size ⅛ through 4. ASME B16.11 socket welding caps are available in different pressure classes, such as 3000, 6000, and 9000.The material of the welded pipe cap needs to comply with relevant regulations, typically using forged or cast steel or stainless steel. The dimensions of socket welding caps according to ASME B16.11 standard as follows:

ASME B16.11 Socket Welding Caps Dimensions:

ASME B16.11 Socket Welding Cap

| Nominal Pipe Size | Socker Bore Dia., B | Socket Wall Thickness, C [Note (1)] | Socket Depth,J | End Wall Thickness, K | ||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||

| Max. | Min. | Avg. | Min. | Avg. | Min. | Avg. | Min. | Min. | Min. | Min. | Min. | |

| ⅛ | 11.2 | 10.8 | 3.18 | 3.18 | 3.96 | 3.43 | … | … | 9.5 | 4.8 | 6.4 | … |

| ¼ | 14.6 | 14.2 | 3.78 | 3.30 | 4.60 | 4.01 | … | … | 9.5 | 4.8 | 6.4 | … |

| ⅜ | 18.0 | 17.6 | 4.01 | 3.50 | 5.03 | 4.37 | … | … | 9.5 | 4.8 | 6.4 | … |

| ½ | 22.2 | 21.8 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 9.5 | 6.4 | 7.9 | 11.2 |

| ¾ | 27.6 | 27.2 | 4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 12.5 | 6.4 | 7.9 | 12.7 |

| 1 | 34.3 | 33.9 | 5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 12.5 | 9.6 | 11.2 | 14.2 |

| 1¼ | 43.1 | 42.7 | 6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 12.5 | 9.6 | 11.2 | 14.2 |

| 1½ | 49.2 | 48.8 | 6.35 | 5.54 | 8.92 | 7.80 | 12.70 | 11.12 | 12.5 | 11.2 | 12.7 | 15.7 |

| 2 | 61.7 | 61.2 | 6.93 | 6.04 | 10.92 | 9.50 | 13.84 | 12.12 | 16.0 | 12.7 | 15.7 | 19.0 |

| 2½ | 74.4 | 73.9 | 8.76 | 7.67 | … | … | … | … | 16.0 | 15.7 | 19.0 | … |

| 3 | 90.3 | 89.8 | 9.52 | 8.30 | … | … | … | … | 16.0 | 19.0 | 22.4 | … |

| 4 | 115.7 | 115.2 | 10.69 | 9.35 | … | … | … | … | 19.0 | 22.4 | 28.4 | … |

General note: Dimensions are in millimeters.

Note (1): Average of socket wall thickness around periphery shall not be less than listed values.The minimum values are permitted in localized areas.

ASME B16.11 Socket Welding Cap

| Nominal Pipe Size | Socker Bore Dia., B | Socket Wall Thickness, C [Note (1)] | Socket Depth, J | End Wall Thickness, K | ||||||||

| 3000 | 6000 | 9000 | 3000 | 6000 | 9000 | |||||||

| Max. | Min. | Avg. | Min. | Avg. | Min. | Avg. | Min. | Min. | Min. | Min. | Min. | |

| ⅛ | 0.440 | 0.420 | 0.125 | 0.125 | 0.156 | 0.135 | … | … | 0.38 | 0.19 | 0.25 | … |

| ¼ | 0.575 | 0.555 | 0.149 | 0.130 | 0.181 | 0.158 | … | … | 0.38 | 0.19 | 0.25 | … |

| ⅜ | 0.710 | 0.690 | 0.158 | 0.138 | 0.198 | 0.172 | … | … | 0.38 | 0.19 | 0.25 | … |

| ½ | 0.875 | 0.855 | 0.184 | 0.161 | 0.235 | 0.204 | 0.368 | 0.322 | 0.38 | 0.25 | 0.31 | 0.44 |

| ¾ | 1.085 | 1.065 | 0.193 | 0.168 | 0.274 | 0.238 | 0.385 | 0.337 | 0.50 | 0.25 | 0.31 | 0.50 |

| 1 | 1.350 | 1.330 | 0.224 | 0.196 | 0.312 | 0.273 | 0.448 | 0.392 | 0.50 | 0.38 | 0.44 | 0.56 |

| 1¼ | 1.695 | 1.675 | 0.239 | 0.208 | 0.312 | 0.273 | 0.478 | 0.418 | 0.50 | 0.38 | 0.44 | 0.56 |

| 1½ | 1.935 | 1.915 | 0.250 | 0.218 | 0.351 | 0.307 | 0.500 | 0.438 | 0.50 | 0.44 | 0.50 | 0.62 |

| 2 | 2.426 | 2.406 | 0.273 | 0.238 | 0.430 | 0.374 | 0.545 | 0.477 | 0.62 | 0.50 | 0.62 | 0.75 |

| 2½ | 2.931 | 2.906 | 0.345 | 0.302 | … | … | … | … | 0.62 | 0.62 | 0.75 | … |

| 3 | 3.560 | 3.535 | 0.375 | 0.327 | … | … | … | … | 0.62 | 0.75 | 0.88 | … |

| 4 | 4.570 | 4.545 | 0.421 | 0.368 | … | … | … | … | 0.75 | 0.88 | 1.12 | … |

General note: Dimensions are in inches.

Note (1): Average of socket wall thickness around periphery shall not be less than listed values.The minimum values are permitted in localized areas.

Meanwhile,we manufacture & supply different types of socket welding pipe fittings according to ASME B16.11 standard as follows:

- ASME B16.11 socket welding 45° elbows,socket welding 90° elbows

- ASME B16.11 socket welding tees

- ASME B16.11 socket welding crosses

- ASME B16.11 socket welding bosses

- ASME B16.11 socket welding caps

- ASME B16.11 socket welding couplet

- ASME B16.11 socket welding full coupling,socket welding half coupling

Haihao Group manufacture & supply & export pipeline products more than 30 years,which contain butt welding pipe fittings (elbows, tees, reducers, caps, bends, crosses, etc), forged pipe fittings (socket weld/threaded elbows, tees, reducers, crosses, couplings, union, outlet, nipple, etc), steel pipes(seamless steel pipes, SAW/ERW steel pipes, casing and tubing pipes, etc) and forged flanges(weld neck flange, slip on flange, blind flange, lap joint flange, plate flange, threaded flange, socket weld flange, orifice flange, spectacle blind flange, weld overlay cladding flange,etc).We supply the products in different standards such as ANSI/ASME, ASTM, BS, EN, JIS, GOST, ISO, MSS, etc.If you want to know more about our pipeline products,please email us:sales@haihaogroup.com