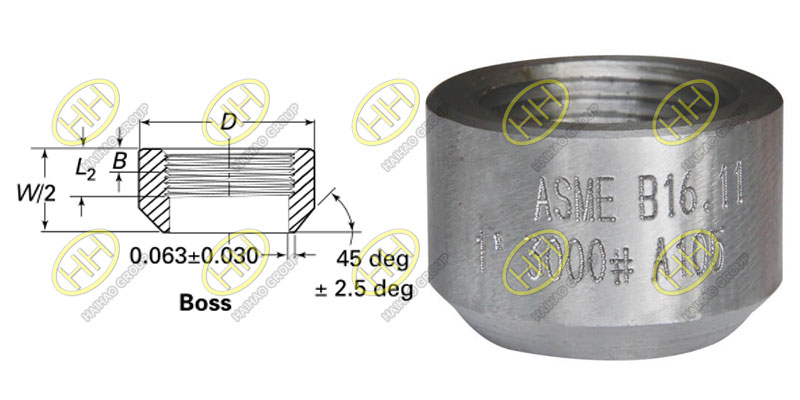

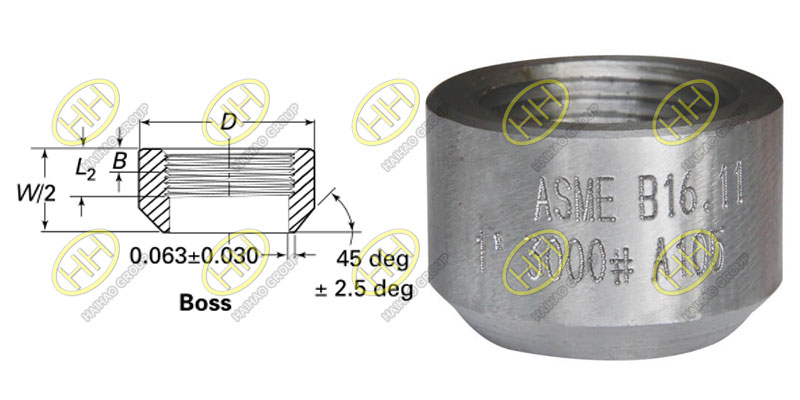

ASME B16.11 Threaded Bosses

ASME B16.11 threaded bosses stand as threaded connectors that exemplify precision and versatility in high-pressure piping systems. These bosses, designed with male threads, are engineered to thread seamlessly into female-threaded pipes or fittings, creating a robust and leak-resistant joint.

Our threaded bosses are dimensioned according to B16.11 standard, including pressure-temperature ratings, dimensions, marking, tolerances and material requirements.Threaded bosses are available in different pressure classes, ranging from 3000 to 6000. The choice of materials for ASME B16.11 threaded bosses is crucial and depends on the specific requirements of the application. Common materials include:

- Carbon Steel (ASTM A105): Suitable for general applications with good strength.

- Alloy Steel (ASTM A182 F11, F22): Offers enhanced corrosion resistance and high-temperature strength.

- Stainless Steel (ASTM A182 F304, F316): Provides excellent corrosion resistance, making it suitable for corrosive environments.

ASME B16.11 Threaded Bosses Dimensions:

ASME B16.11 Threaded Bosses

| Nominal Pipe Size | Outside Diameter, D | End-to-End Boss, W | Minimum Length of Thread[Note(1)] 3000/6000 | ||

| 3000 | 6000 | 3000/6000 | B | L2 | |

| ⅛ | 16 | 22 | 32 | 6.4 | 6.7 |

| ¼ | 19 | 25 | 35 | 8.1 | 10.2 |

| ⅜ | 22 | 32 | 38 | 9.1 | 10.4 |

| ½ | 28 | 38 | 48 | 10.9 | 13.6 |

| ¾ | 35 | 44 | 51 | 12.7 | 13.9 |

| 1 | 44 | 57 | 60 | 14.7 | 17.3 |

| 1¼ | 57 | 64 | 67 | 17.0 | 18.0 |

| 1½ | 64 | 76 | 79 | 17.8 | 18.4 |

| 2 | 76 | 92 | 86 | 19.0 | 19.2 |

| 2½ | 92 | 108 | 92 | 23.6 | 28.9 |

| 3 | 108 | 127 | 108 | 25.9 | 30.5 |

| 4 | 140 | 159 | 121 | 27.7 | 33.0 |

General Note:

(1) Dimensions are in millimeters.

(2)The wall thickness away from the threaded ends shall meet the minimum wall thickness requirements of Table 6.1-3 for the appropriate NPS and Class Designation fitting.

NOTE:(1)Dimension B is minimum length of perfect thread.The length of useful thread (B plus threads with fully formed roots and flat crests)shall not be less than L2(effective length of external thread) required by ASME B1.20.1 (see 1.1 below).

ASME B16.11 Threaded Bosses Dimensions:

ASME B16.11 Threaded Bosses

| Nominal Pipe Size | Outside Diameter, D | End-to-End Boss, W | Minimum Length of Thread[Note(1)] 3000/6000 | ||

| 3000 | 6000 | 3000/6000 | B | L2 | |

| ⅛ | 0.62 | 0.88 | 1.25 | 0.25 | 0.2639 |

| ¼ | 0.75 | 1.00 | 1.38 | 0.32 | 0.4018 |

| ⅜ | 0.88 | 1.25 | 1.50 | 0.36 | 0.4078 |

| ½ | 1.12 | 1.50 | 1.88 | 0.43 | 0.5337 |

| ¾ | 1.38 | 1.75 | 2.00 | 0.50 | 0.5457 |

| 1 | 1.75 | 2.25 | 2.38 | 0.58 | 0.6828 |

| 1¼ | 2.25 | 2.50 | 2.62 | 0.67 | 0.7068 |

| 1½ | 2.50 | 3.00 | 3.12 | 0.70 | 0.7235 |

| 2 | 3.00 | 3.62 | 3.38 | 0.75 | 0.7565 |

| 2½ | 3.62 | 4.25 | 3.62 | 0.93 | 1.1380 |

| 3 | 4.25 | 5.00 | 4.25 | 1.02 | 1.2000 |

| 4 | 5.50 | 6.25 | 4.75 | 1.09 | 1.3000 |

General Notes:

(1)Dimensions are in inches.

(2)The wall thickness away from the threaded ends shall meet the minimum wall thickness requirements of Table 6.1-3C for the appropriate NPS and class Designation fitting.

NOTE:(1)Dimension B is minimum length of perfect thread.The length of useful thread(B plus threads with fully formed roots and flat crests)shall not be less than L2(effective length of external thread) required by ASME B1.20.1 (see 1.1 below).

1.1 Threaded Fittings

1.1.1 Wall Thickness.The body or end wall thickness of threaded fittings shall be equal to or greater than the minimum values,G,as shown in Tables.

1.1.2 Internal Threading.All fittings with internal threads shall be threaded with American National Standard Taper Pipe Threads (ASME B1.20.1).Variations in threading shall be limited to one turn large or one turn small from the gaging notch when using working gages.The reference point for gaging is the starting end of the fitting,provided the chamfer does not exceed the major diameter of the internal thread.

When a chamfer on the internal thread exceeds this limit,the reference point becomes the last thread scratch on the chamfer cone.

1.1.3 External Threads.All externally threaded fittings shall be threaded with American National Standard Taper Pipe Threads (ASME B1.20.1),and the variation in threading shall be limited to one turn large or one turn small from the gage face of ring when using working gages.The reference point for gaging is the end of the thread,provided the chamfer is not smaller than the minor diameter of the external thread.When a chamfer on the external thread exceeds this limit, the reference point becomes the last thread scratch on the chamfer cone.

1.1.4 Countersink or Chamfer.All internal threads shall be countersunk a distance not less than one-half the pitch of the thread at an angle of approximately 45 deg with the axis of the thread,and all external threads shall be chamfered at an angle of 30 deg to 45 deg from the axis,for easier entrance in making a joint and protection of the thread.Countersinking and chamfering shall be concentric with the threads.The length of threads specified in all tables shall be measured to include the countersink or chamfer.

Meanwhile,we manufacture & supply different types of threaded pipe fittings according to ASME B16.11 standard as follows:

- ASME B16.11 threaded 45° elbows,threaded 90° elbows

- ASME B16.11 threaded street elbows

- ASME B16.11 threaded tees

- ASME B16.11 threaded crosses

- ASME B16.11 threaded full couplings,threaded half couplings

- ASME B16.11 threaded pipe caps

- ASME B16.11 threaded bosses

- ASME B16.11 threaded couplets

- ASME B16.11 plugs and bushings

Haihao Group manufacture & supply & export pipeline products more than 30 years,which contain butt welding pipe fittings(elbows,tees,reducers,caps,bends,crosses,etc),forged pipe fittings(socket weld/threaded elbows, tees, reducers, crosses, couplings, union, outlet, nipple, etc),steel pipes(seamless steel pipes, SAW/ERW steel pipes, casing and tubing pipes,etc) and forged flanges(weld neck flange, slip on flange, blind flange, lap joint flange, plate flange, threaded flange, socket weld flange, orifice flange, spectacle blind flange, weld overlay cladding flange,etc).We supply the products in different standards such as ANSI/ASME, ASTM, BS, EN, JIS, GOST, ISO, MSS, etc.If you want to know more about our pipeline products,please email us:sales@haihaogroup.com