-

In the pipeline industry,PMI is often mentioned.What is PMI? PMI is abbreviation for positive material identification.It is one of the non-destructive analysis of a metallic alloy to ensure product or alloy quality as per requirement. PMI testing is very q ...

-

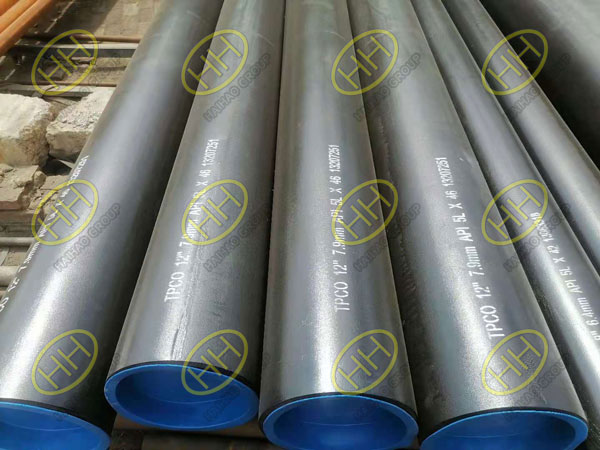

Today, a batch of seamless steel tubes has been produced and ready to be shipped to Canada. About a month ago, a customer from Canada sent us an inquiry, mainly about seamless steel pipes. The products in the inquiry are as follows: Pipe, seamless, size: 2 ...

-

Hebei Haihao Group specialized in producing flange, pipe fittings and pipe. We have lots of customers from all over the world. Some clients couldn’t come to inspect the goods for their orders. So they will arrange third party inspection to ensure the ...

-

Next, let’s learn about the quality problems and solutions of forgings in quenching and cooling: Insufficient hardness and enough hardening depth: quenching cooling rate is low is forging quenching hardness is insufficient, the cause of the uneven ha ...

-

Recently, the production of cement lined steel pipes has been completed, and passed the inspection. They have been ready to ship to the England. The pipe with cement lining About a month ago, I received an inquiry from a British customer. The products in t ...

-

P265GH is a low alloy high temperature structural steel, in accordance with the European standard EN10253-2. It is a kind of European standard boiler vessel plate. In P265GH steel grade, G stands for others, H stands for high temperature, P stands for stee ...

-

Forging is a workpiece or blank obtained by forging and deforming a metal blank. The mechanical properties of metal billet can be changed by applying pressure to make it produce plastic deformation. The looseness of metal can be eliminated by forging. Hole ...

-

I received an inquiry from UAE this week. The customer requires all products to be made PWHT, let’s see what is the PWHT? Post weld heat treatment (PWHT) process refers to a welding heat treatment process in which the welds are heated to a certain te ...

-

The fracture inspection is one of the methods to check the quality of steel pipeline products. There are mainly the following fracture types: ductile fracture, brittle fracture, porcelain fracture, lamellar fracture, stony fracture, graphite fracture, etc. ...

-

The porosity of welding seam will not only affect the compactness of welding seam, cause pipeline leakage, but also become the inducing point of pipeline corrosion, and will reduce the strength and toughness of welding seam seriously. The main factors that ...

-

As the pipeline has been buried in the ground for a long time, with the passage of time, the characteristics of the external soil and the settlement of the terrain will affect the corrosion, leakage, site, perforation and other factors of the pipeline, res ...

-

I received an inquiry from a customer in Brazil as follows,”FLANGE BLIND, DN 6IN, ASME B16.5, 150LBS ASTM A105N RF, INTERNAL COATED WITH STELLITE”. About STELLITE,let’s learn about it. Stellite alloy is a kind of hard alloy that can resis ...

-

Today, the production of the Egyptian customer’s order has been completed and the goods have been delivered. About one month ago, I received an inquiry from an Egyptian customer. The inquiry products are mainly seamless pipes, length: 12M/PC, size: 1 ...

-

Hebei Haihao Group is a professional production of flange fittings factory, we have the most complete flange equipment, at the same time we will also supply accessories together What is gasket ? The contact surface where the gasket is inserted between th ...

-

The elbow is made of cast iron, stainless steel, alloy steel, malleable iron, carbon steel, non-ferrous metal and plastic. Elbow connection methods are: direct welding (the most commonly used way) flange connection, hot melt connection, electric fusion con ...

-

A customer needs hot rolled steel pipe this week, but only cold rolled steel pipe due to the special wall thickness.Today let’s learn about the difference between hot rolled steel pipe and cold drawn steel pipe. Cold drawn steel pipe: Cold drawn stee ...

-

Seamless steel pipes are everywhere in our life. The manufacturing process of seamless steel tube begins with solid round billet. Then the billet is heated to high temperature, stretched and stretched until the hollow tube is hollow. Recently, I have a Ger ...

-

316L stainless steel pipe is a commonly used stainless steel pipe. Because of its excellent corrosion resistance, it is widely used in the chemical industry. Its raw material 316L is a kind of stainless steel containing a chemical component – molybde ...

-

Hebei Haihao Group is a manufactory specialized in producing flange, pipe fittings and pipe, we can many certificates to ensure the quality. Every month there will be customers to place steel pipe orders. Today we are going to look at the areas where seaml ...

-

According to the different manufacturing process of steel tubes can be hot rolled, extrusion, cold drawn and cold rolled these several main types. Next, we will mainly introduce the hot rolling production process. The production process of hot rolled steel ...