-

Detection of cracks or defects in metal materials or components. The commonly used flaw detection methods are: X-ray flaw detection, ultrasonic flaw detection, magnetic particle inspection, penetrant inspection, eddy current flaw detection and gamma ray fl ...

-

Nondestructive testing(NDT) is a testing method to check the surface and internal quality of the inspected parts on the premise of not damaging the working state of the workpiece or raw materials. Method The commonly used nondestructive testing methods are ...

-

Hebei Haihao offers one of the most extensive selections of black and galvanized malleable iron fittings in the industry. Available in 13 diameters from 1/8″ to 6″, every fitting is produced to exact specifications. All galvanized products are ...

-

What is Galvanized Pipe Nipple? For laymen, they would never have thought that galvanized nipple is a pipe fitting, but the fact is this word have been using for more than 400 years in plumbing and engineering. We can’t finger out the first usage of ...

-

A pipe nipple is a kind of fitting commonly used in industrial pipeline connection.There are common screw nipples, which are divided into double head outer thread, single head outer thread and flat head outer thread. In addition, there are also nipples con ...

-

In recent years, branch (Olet) is widely used in foreign countries, which is used for branch pipe connection, instead of the traditional branch pipe connection types such as reducing tee, reinforcing plate and strengthening pipe section. It has outstanding ...

-

In the production and processing of pipe fittings, hot galvanizing and cold galvanizing methods are often used to prevent pipe fittings from rusting, especially galvanized elbow and galvanized size head. Customers often according to their own needs and act ...

-

For a piping component,it will have a working pressure,proof test pressure and burst pressure.What is the difference between these pressure specifications for pipe fittings? The working pressure is the working conditions range of the pipe fittings or flang ...

-

Non-Destructive Testing(NDT) is used in inspecting,testing,or evaluating materials,components or assemblies for discontinuities,or differences in characteristics without destroying the pipes,fittings or flanges.That means the products can still be used whe ...

-

The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount of energy absor ...

-

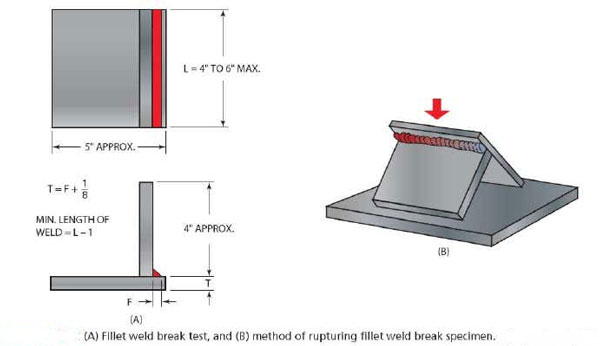

Destructive weld testing, as the name suggests, involves the physical destruction of the completed weld in order to evaluate its characteristics. This method of testing is used frequently for a number of applications. Some of these applications include wel ...

-

Destructive weld testing, as the name suggests, involves the physical destruction of the completed weld in order to evaluate its characteristics. This method of testing is used frequently for a number of applications. Some of these applications include wel ...

-

Heat treatment process is an important part of pipe manufacturing. Through the heat treatment steps of heating, heat preservation and cooling, the work hardening, residual stress and metal deformation defects produced in the forming process can be eliminat ...

-

The main features of epoxy bituminous paint: Interpenetrating the network anti-corrosion layer.Chlorosulfonated polyethylene rubber with excellent anti-corrosion properties is used to modify traditional epoxy coal bitumen to form an interpenetrating networ ...

-

3PE anti-corrosion pipe fittings refer to 3-coating polyolefin coating (mapec) external anti-corrosion pipe fittings. The anti-corrosion pipe fittings include elbow, tee, reducer, and other products. It is a common anti-corrosion pipe fittings. Other antic ...

-

There are many uses of 3PE anti-corrosion pipe fittings, and its function is really wide coverage. 1.Underground water supply and drainage, underground shotcreting, positive and negative pressure ventilation, gas drainage, fire sprinkler and other pipe net ...

-

In China, 3PE anticorrosive steel pipes have been applied in oil and gas systems. nearly 4,000 kilometers of the national key project West-East Gas Pipeline have used 3PE anti-corrosion steel pipes. We have also exported a lot of 3PE coated steel pipes to ...

-

Q235B spiral tube is a commonly used raw material in spiral tubes. It is a spiral seam steel pipe welded with strip steel coil as the raw material and active double wire double-sided submerged arc welding. The main technical characteristics of the spiral s ...

-

Pipe threads are threads located on the pipe wall for connection. There are 55 degree unsealed pipe threads and 55 degree sealed pipe threads. Mainly used for pipeline connection, so that its internal and external threads are closely matched, there are two ...

-

The anticorrosion property of pipe is effectively improved by galvanizing. And the steel pipe galvanized mainly hot dip galvanized, pre-galvanized and galvanized three common methods, according to the final use of the steel pipe environment to choose the c ...