-

In fact, according to the content of chromium and nickel are 304 stainless steel, the composition contains 18% chromium (CR) and 8% nickel (Ni), but the main difference lies in the difference in carbon content. Among the three, the highest carbon content i ...

-

Conceptually, FPSOs have given oil and gas companies a lot of freedom and versatility with regards to exploration and extraction. FPSOs enables companies to produce oil & gas and explore increasingly remote areas at a cheaper price in comparison to tra ...

-

A floating production storage and offloading (FPSO) installation is a floating facility, usually based on a (converted) oil tanker hull. It is equipped with hydrocarbon processing equipment for separation and treatment of crude oil, water and gases, arrivi ...

-

A flange is used for attachment to another object, for instance, the end of a pipe. It can also be used for connection between two equipments, e.g. reducer flange, which is used for connection between the motor and the reducer, as well as the reducer and o ...

-

The process of manufacturing the ASTM specified A234 WP9 pipe fittings is referred to as wrought. Wrought grade fittings mean the alloy has been either cast or forged. The material used to produce ASTM A234 WP9 is low content alloy steel. One of the featur ...

-

Comparison of cold-rolled and hot rolled seamless steel pipes and their advantages and disadvantages

There are mainly two kinds of stainless steel seamless steel pipes, namely, cold rolling seamless steel pipes and hot-rolled seamless steel pipes. The difference between them is obvious, each has its own advantages and disadvantages. Difference between col ... -

The classification is different 1.Straight seam steel pipe: it is divided into metric electric welding steel pipe, electric welding thin wall pipe and transformer cooling oil pipe 2.Seamless steel pipe: seamless pipe is divided into hot rolled pipe, cold r ...

-

The uneven thickness of the thick-walled steel tube is mainly reflected in the uneven thickness of the spiral wall, the uneven thickness of the linear wall and the thick and thin wall at the head and tail. There are mainly three aspects as follows: 1.The c ...

-

Surface hardening of thick-walled steel tubes is a method of local quenching, in which a certain depth of hardened layer is obtained on the surface of the workpiece, while the core remains unquenched. When the surface is quenched, the surface of the workpi ...

-

For precision steel tubes, hot rolling is compared to cold rolling, which is rolled below the recrystallization temperature, while hot rolling is rolled above the recrystallization temperature. Advantages of hot rolled precision steel tube: It can destroy ...

-

Centerline segregation occurs as a positive concentration of alloying elements in the mid-thickness region of continuously cast slab. Depending upon its severity, it may affect mechanical properties and potentially downstream processing such as weldability ...

-

An API 5L line pipes manufactured in two varieties PSL 1 and PSL 2. But what is PSL? PSL stands for Product Specification Levels. Pipes are used in different types of environments such as corrosive and non-corrosive.Pipes used in the severe corrosive envir ...

-

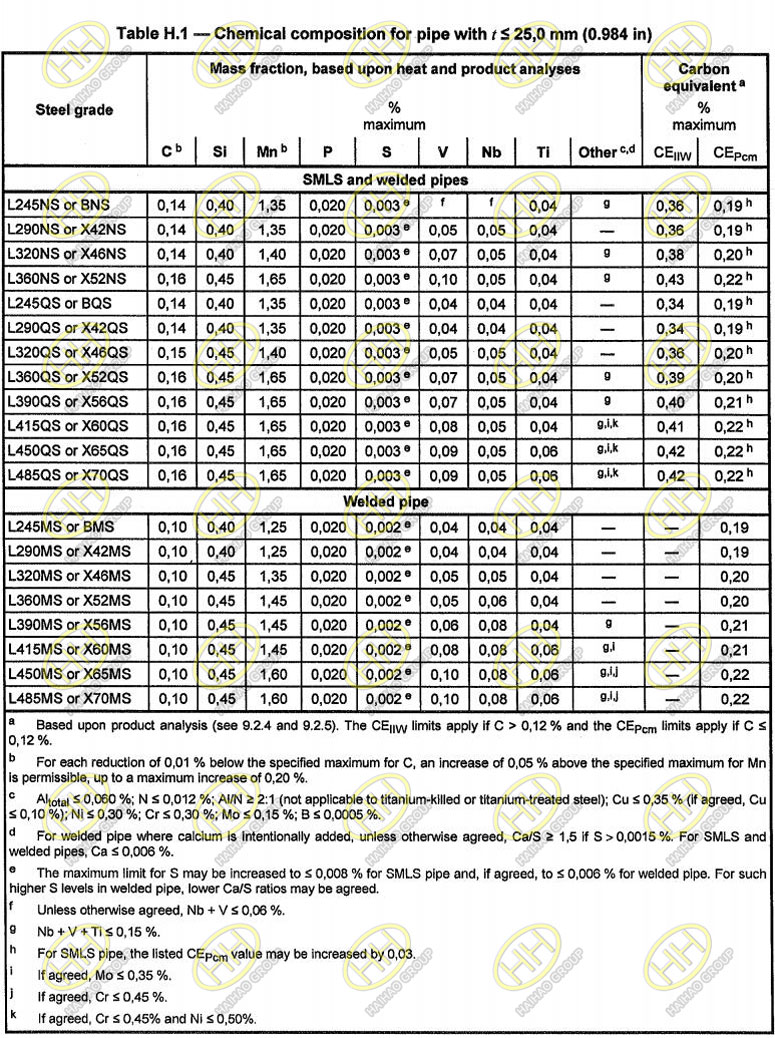

Last article we know what is sour service pipe,today let’s see the chemical composition and mechanical properties of API 5L sour service pipe. API 5L Sour Service pipe Chemical Composition API 5L Sour Service pipe Chemical Composition 1). C and carbo ...

-

Sour services steel pipe is applied for pipelines in the corrosive environment. As we know, line pipe corrosion is an important factor affecting its safety service and service life. It will cause the leakage of oil and gas pipeline, some cases even explosi ...

-

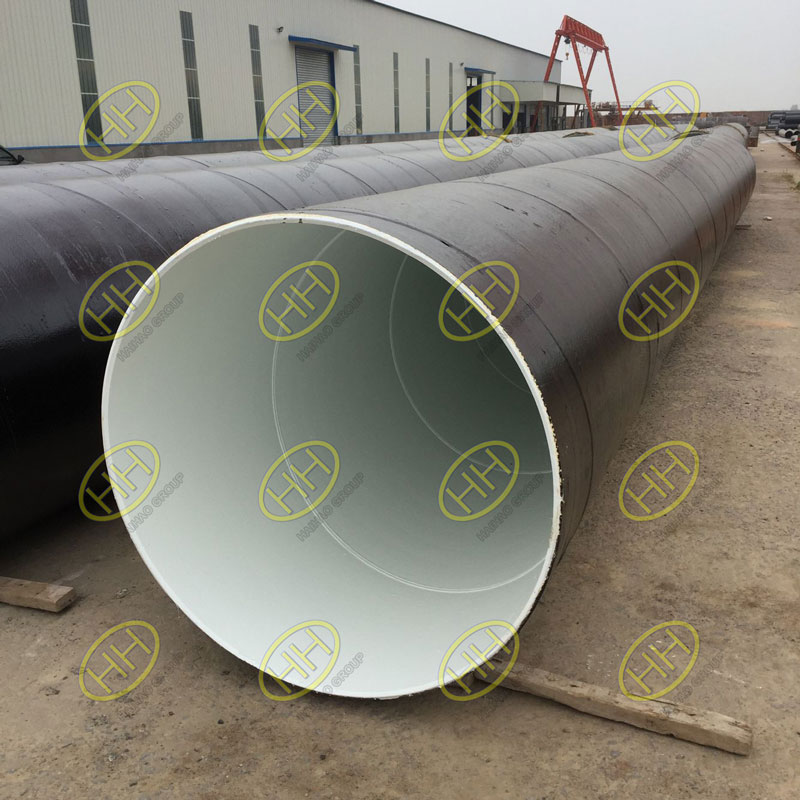

In last article,we learned what is 3PE coated steel pipe.Today let’s see advantages of 3PE coated pipe. Durable lifetime 3PE epoxy coated steel pipe have good stability and anti-aging performances under the normal work temperature and pressure condit ...

-

What is 3PE Epoxy coating pipe? The 3PE Epoxy coated steel pipe is with 3 layer coatings, first FBE coating, middle is adhesive layer, outside polyethylene layer. 3PE coating pipe is another new product developed on the FBE coating basis since 1980s, which ...

-

You might think heat exchangers would always need to be made of metals, which quickly absorb and conduct heat—and many of them are. But heat exchangers can also be made of ceramics, composites (based on either metals or ceramics), and even plastics (polyme ...

-

Saving energy is a huge and costly problem for factory bosses and it’s one reason they often install devices called heat exchangers to salvage as much heat as possible from waste gases. Heat exchangers have lots of other familiar uses too. Engines in ...

-

You can see heat exchangers in all kinds of places, usually working to heat or cool buildings or helping engines and machines to work more efficiently. Refrigerators and air-conditioners, for example, use heat exchangers in the opposite way from central he ...

-

Suppose you have a gas central heating furnace (boiler) that heats hot-water radiators in various rooms in your home. It works by burning natural gas, making a line or grid of hot gas jets that fire upward over water flowing through a network of pipes. As ...