-

At Haihao Group, we prioritize delivering exceptional products that meet the highest quality standards. We are proud to announce that our pipe fittings have successfully passed a rigorous third-party quality inspection conducted by INTERTEK, a renowned glo ...

-

Tee fittings play a crucial role in any piping system, enabling efficient flow distribution and seamless connections. To ensure the longevity and reliability of your tee installations, it is essential to follow the correct installation methods and implemen ...

-

We are excited to share with you the intricate manufacturing process behind our exceptional pipe caps. Designed to safeguard pipe ends and ensure optimal performance, our pipe caps are meticulously crafted using state-of-the-art techniques and premium mate ...

-

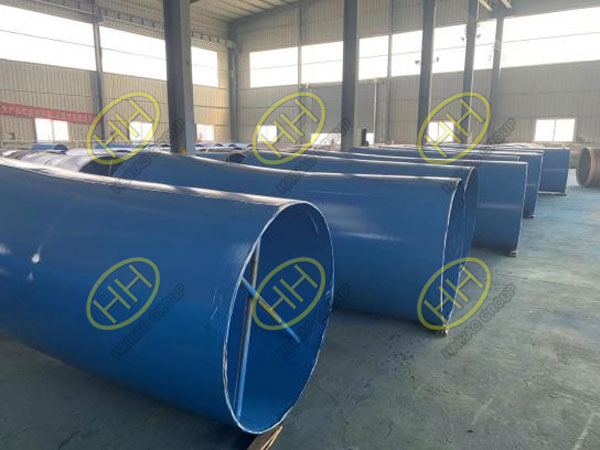

Haihao Group takes immense pride in providing high-quality pipe solutions to our global clientele. In this article, we highlight the benefits of 3PE coating, focusing on a recent order from a Russian customer who recognized the importance of corrosion prot ...

-

We are delighted to introduce our premium-grade ANSI/ASME B16.9 seamless elbow ASTM A234 WPB 90° 6″ SCH 40, designed to optimize the performance and reliability of your piping systems. With our commitment to excellence and adherence to industry stand ...

-

In the dynamic world of nuclear power plants, where the demands for corrosion-resistant, high-temperature pipe fittings are paramount, Haihao Group has emerged as a trusted partner. This is the story of our extraordinary collaboration with a nuclear power ...

-

In the world of pipeline systems, concentric reducers play a crucial role in facilitating smooth flow transitions and optimizing performance. At Haihao Group, we take pride in our meticulous approach to manufacturing concentric reducers, which includes a c ...

-

Since June, the prices of cold and hot rolled coil plates in China have continued to rise, and the market trading situation is still good. Steel traders generally hold a cautious and optimistic attitude towards the future market. Relevant scholars predict ...

-

We are thrilled to announce that a batch of high-quality BS 1965 EN 10253-4 S235JRG2 reducing tees, sized 8×6-inch, has been successfully ordered by one of our valued customers. This remarkable product combines superior functionality with exceptional ...

-

At Haihao Group, we understand the critical role that fittings play in optimizing the performance and efficiency of your piping system. One such essential component is the ANSI/ASME B16.9 butt weld fitting concentric reducer. In this article, we highlight ...

-

We are thrilled to announce that Haihao Group is now offering SAW pipe 1118X9.53X6000MM API 5L GR.B PSL1 with a premium 3PE coating. This cutting-edge coating technology provides exceptional protection against corrosion, ensuring the longevity and reliabil ...

-

Flange leakage can be a major concern in industrial piping systems, leading to costly downtime, safety hazards, and environmental risks. At Haihao Group, we understand the importance of reliable and leak-free connections, which is why we’re here to g ...

-

Flanges are critical components in various industries, playing a pivotal role in ensuring secure and leak-free connections in piping systems. Selecting the appropriate material for flanges is essential to achieve optimal performance, longevity, and reliabi ...

-

We are delighted to announce that Haihao Group has implemented state-of-the-art EDM (Eddy Current Testing) technology to ensure the exceptional quality and reliability of our plastic coated pipes. This cutting-edge testing method has revolutionized our ins ...

-

Corrosion is a significant concern in industries that rely on pipe fittings for fluid transportation and containment. At Haihao Group, we understand the importance of preserving the integrity and longevity of your pipe fittings. That’s why we offer a ...

-

At Haihao Group, we take pride in delivering exceptional products that meet and exceed our customers’ expectations. In our continuous pursuit of excellence, we employ innovative techniques to enhance the durability and protection of our offerings. On ...

-

Protective coatings are crucial for extending the lifespan of industrial products, and our team at Haihao Group takes coating treatment seriously. For the Singapore customer’s recent order, we chose a special type of coating to ensure maximum protect ...

-

Ensuring the highest quality of our products is always our top priority at Haihao Group. This is why we take quality inspections very seriously, both in our factory and through third-party inspections. In this article, we will introduce the quality inspect ...

-

Pipe coatings are essential to protect pipes from corrosion, erosion, and damage caused by harsh environmental conditions. There are several types of pipe coatings available, each with its own advantages and disadvantages. In this article, we will explain ...

-

Pipe fittings are essential components used in various industrial applications such as oil and gas, chemical processing, power generation, and many others. These fittings must be protected from corrosion, wear and tear, and other environmental factors that ...