-

Large-diameter straight-seam steel pipes are widely used in natural gas, petroleum, chemical industry and other fields, generally referring to straight-seam steel pipes with an outer diameter of over 500mm. The common product models are: φ 325× 8-20, φ 426 ...

-

Metal bellows is generally composed of bellows, mesh sleeve and joint. Corrugated pipe is the metal corrugated pipe itself, playing the role of flexibility; The net cover plays an active role in strengthening and shielding; Joint quality plays an important ...

-

1.The layout design shall meet the requirements of process piping and instrument flow diagram. 2.The pipeline layout shall be planned as a whole, safe, reliable, economical and reasonable, meet the requirements of construction, operation, maintenance and o ...

-

Driven by the the Belt and Road policy, Haihao’s export business has been increasing in recent years. Previously, a Bulgarian customer ordered pipe fittings in Haihao, including various types of flanges, elbows, tees, and other supporting products, w ...

-

Recently, the reporter learned from China Oilfield Services Iraq Branch that the company and Zhenhua Petroleum Dongba Petroleum Co., Ltd. signed a general contract for the drilling of 32 wells in the south section of East Baghdad Oilfield in Baghdad, the c ...

-

Not long ago, the commissioning of the world’s largest natural gas processing FPSO was completed. Reviewing the whole supply process, when we just received the customer’s product requirements, the engineers of the technical department of Haihao ...

-

On January 7, the world’s largest natural gas processing floating storage and unloading platform N999 Tortue FPSO, designed and built by Qidong COSCO Marine, completed all commissioning work. After the completion of the sea trial, it is planned to tr ...

-

Endeavour for 40 years, passion for the future. In 1982, Hebei Haihao Group officially established its factory in Mengcun County, the hometown of pipe fittings in China. From a few people to more than 700 people, Haihao has always put product quality and s ...

-

Today, a batch of steel pipes ordered by Dutch customers have been inspected and ready for packaging and shipment. The customer signed a supply contract with Haihao last year, ordering products including flanges, elbows, and steel pipes. The flanges and el ...

-

Seamless steel pipe is a steel pipe perforated by a whole round steel, with no weld on the surface. It can be divided into general purpose (used for water and gas pipelines and structural parts, mechanical parts) and special purpose (used for boilers, geol ...

-

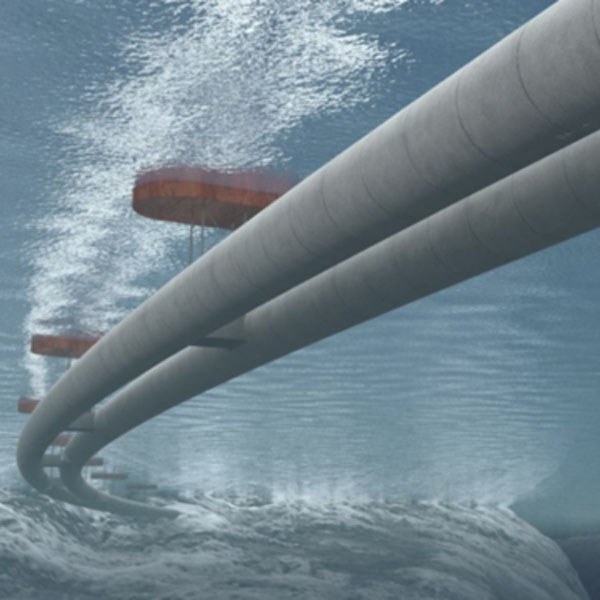

There is a big difference between submarine pipelines and land pipelines. In addition to the working loads borne by the pipelines during normal operation, the submarine pipelines also need to consider the tensile buckling stress and residual stress after t ...

-

The pipeline varies according to the transportation medium,and the requirements for some parameters are different. Only by understanding their differences can we produce pipes with different parameters according to different needs. Now let’s take a l ...

-

The year 2023 is approaching us with vigor and vitality. In the New Year, Haihao Group will stay true to its original intention and forge ahead, working hand in hand with you to create a better world. Haihao Group

-

Qatar is an important member of the the Belt and Road, and the local oil and gas resources are very rich. Driven by the the Belt and Road policy, the products of Haihao Group have been more and more applied in local projects in Qatar. On Monday, the produc ...

-

As we said before, there may be some situations in pipeline engineering where hydrostatic test cannot be carried out. As an enterprise specializing in R&D, production and sales of pipeline engineering supporting products, Haihao Group has professional ...

-

Not long ago, the prefabricated parts ordered by Chilean customers completed the hydrostatic test before delivery. Hydrostatic testing is a commonly used testing method to check the strength and air tightness of pipelines, which is widely used in pipeline ...

-

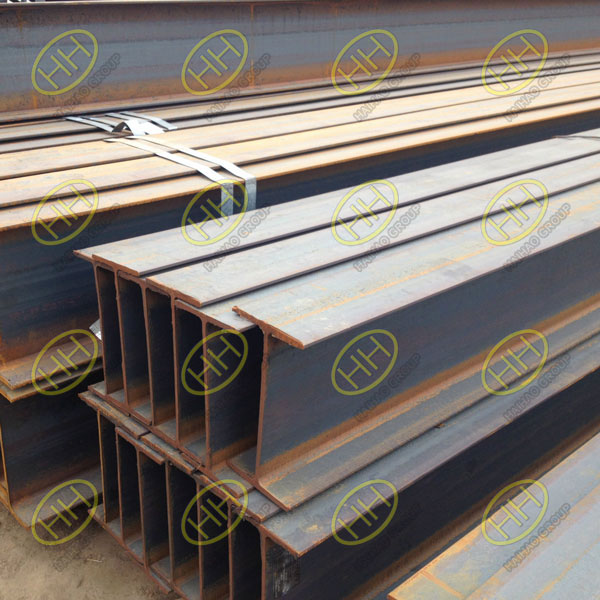

H Beam is a kind of economical and efficient section steel with more optimized section area distribution and more reasonable strength weight ratio. It is named because its section is the same as the “H”. Since all parts of H-shaped steel are ar ...

-

In recent years, clean energy represented by natural gas is developing rapidly in the world. The East Africa region has attracted the attention of the international energy market due to its rich natural gas resources. In particular, the offshore area in th ...

-

A182 F53 is a ferritic-austenitic duplex stainless steel that combines the beneficial properties of both. Due to the high content of chromium and molybdenum in this steel, it has good resistance to pitting corrosion, crevice corrosion and uniform corrosion ...

-

Today, the 2022 China Marine Economy Expo, the 2022 Shenzhen International Ocean Week and the 2022 Shenzhen Ocean Industry Investment Promotion Conference opened in Shenzhen. Haihao Group 9CT005 booth The Expo covers an exhibition area of 60000 square mete ...