-

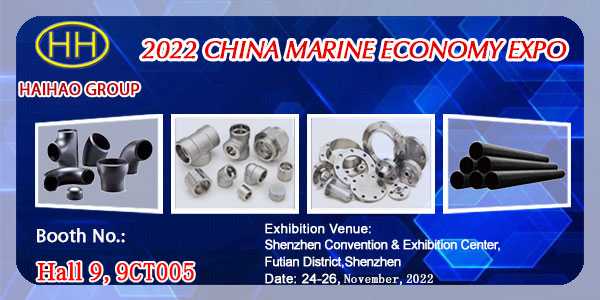

Haihao Group will take many important products to participate in the 2022 China Marine Economy Expo held in Shenzhen Convention and Exhibition Center (Futian District) on November 24-26, 2022, to help China achieve the upgrading and development of pipeline ...

-

The United Arab Emirates is a member of the Organization of Petroleum Exporting Countries (OPEC), and its national economy is dominated by petroleum production and petrochemical industry. With the promotion of the the Belt and Road policy, trade between th ...

-

2022 SSNAME Academic Conference The 2022 SSNAME academic conference was successfully held on November 12. The theme of the conference was “Innovation drives high-quality development of offshore engineering”, Haihao Group was honored to be invit ...

-

Wang Shoujun, president of the Chinese Nuclear Society, introduced at the 23rd Pacific Nuclear Energy Conference held on the 1st that as of June 2022, China had 53 nuclear power generating units in operation, 23 nuclear power generating units under constru ...

-

China Marine Economy Expo, the only national marine economy exhibition in China, is an important window to show the achievements of China’s marine economy development. With the theme of “enabling scientific innovation and sharing deep blue̶ ...

-

At the beginning of this year, British customers signed an order contract with Haihao. Customers want to order flanges, steel pipes, elbows and other piping products in Haihao. By the middle of October, the flanges and steel pipes had been supplied. On Oct ...

-

At the beginning of this year, a customer in Indonesia signed an order contract for a batch of steel pipes with Haihao Group, and the customer wanted to customize a batch of seamless steel pipes. According to the progress of the project, the goods need to ...

-

Last August, Qatari customers ordered a batch of flange and elbow products in Haihao. After more than a year, the required products have been successively delivered to Qatari projects. Last month, the customer said that he needed to customize a few more fl ...

-

With the development of the oil and gas industry, the requirements for the maintenance, replacement and transformation of the pipeline system are also increasing, and the pressure drilling technology has increasingly highlighted its dominant position. Ther ...

-

The National Day is a festival for the whole country to celebrate. Next week, Haihao Group will welcome a week of National Day holiday. Before the holiday, the factory of Haihao Group is still busy. Today, two batches of goods will be delivered to customer ...

-

Argon arc welding technology is a welding technology based on the principle of ordinary electric arc welding, which uses argon to protect the metal welding materials, and uses high current to melt the welding materials on the substrate to form a molten poo ...

-

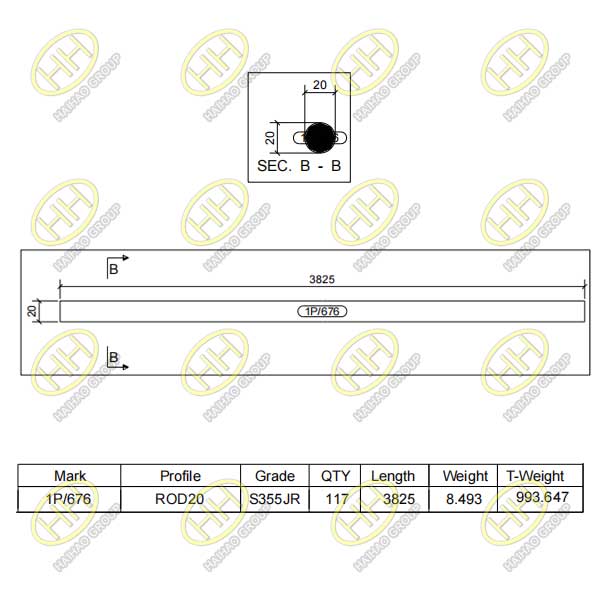

After the regular customer in Pakistan ordered complex skylight tension rods, they purchased another relatively simple goods – Tension Rod 20 with two nuts. According to the drawings and descriptions given by the customer, this product is equivalent ...

-

API 5L and API 5CT are both used for oil & gas industry. But they have difference on three aspects: 1.Standard difference API 5CT: It is a standard of oil casing issued by the American Petroleum Institute. API 5L: Refers to the pipeline pipe API 5L, wh ...

-

Iraq is rich in oil resources, and its crude oil reserves rank fourth in the world. With the implementation of the the Belt and Road policy, China and Iraq have carried out more and more cooperation. Haihao also seized this opportunity and signed many orde ...

-

In July, the procurement costs of various varieties generally decreased month on month, of which metallurgical coke, pellets and scrap steel decreased significantly, by more than 10%. From January to July, the cumulative purchase cost of coking coal increa ...

-

SEMBCORP industry is a top energy, water and maritime engineering group with businesses covering 6 continents. In 2020, Haihao Group cooperated with SEMBCORP industry to complete an FPSO project. The total supply of Haihao Group reached more than 3000 tons ...

-

On August 22, the last batch of flanges will be shipped to the FPSO project in Singapore. From June 2020 to the last batch of supplies now, Haihao Group has supplied more than 110 batches of FPSO projects, with a total supply volume of more than 2000 tons. ...

-

Offshore floating production and storage ship (FPSO) is a key facility for offshore oil development, which is mainly used for the exploitation, processing, storage and transportation of offshore oil, natural gas and other energy. In May 2020, Haihao Group ...

-

With more and more exploiting of seabed oil, FPSO is also applied to the oil projects a lot. We know that if we want to exploit the oil on the sea floor, we need to establish a base. However, for some small-scale oil fields, the cost of base construction m ...

-

Against the background of the global epidemic, the survival of many companies is facing great challenges. As a large foreign trade enterprise, Haihao still insists on development and survives tenaciously. Almost every day, goods are shipped to all parts of ...