Seamless steel pipes manufacturing process

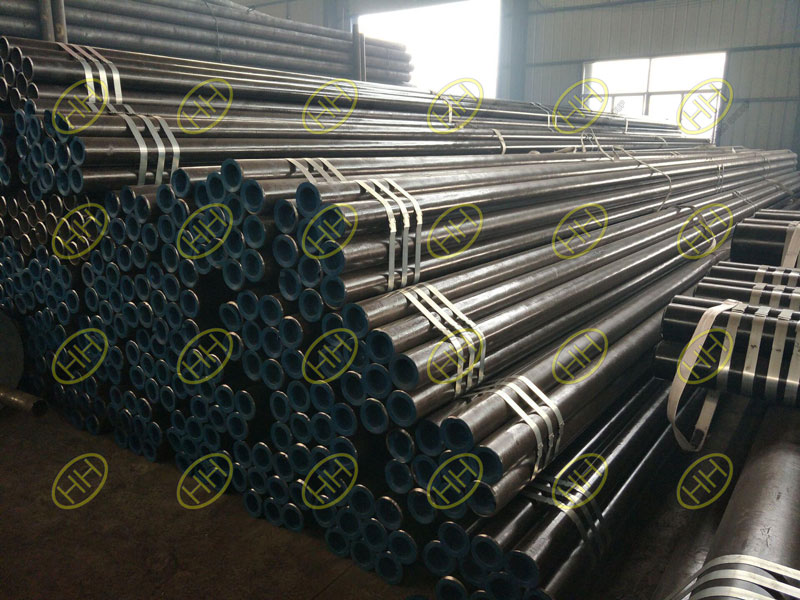

Haihao Group manufacture & supply seamless steel pipes in different dimensions,materials,standards.The seamless steel pipes mean the steel pipes without seams on its surface.The following are the types of seamless steel pipes manufacturing process:

Mandrel mill process of seamless steel pipes:

In the mandrel mill process, a solid round steel billet is used. The billet is heated in a rotary hearth heating furnace and then pierced by a piercer. Once the pierced pipe shell is produced, it is immediately transferred to the floating mandrel mill.The mechanism of rolling the pipe shell through the mandrel mill with the mandrel bar inside acts as a control to create an intermediate standard outside diameter (OD) and a controlled wall thickness, based on the resultant dimension of the mandrel bar set. The mandrel mill shell is then reheated in a reheat furnace so that it can complete the final rolling process and gain its final dimensions and micro-structural qualities. Upon exit from the reheat furnace, the tube receives a high-pressure water descale, removing the iron oxide scale that formed in the reheat furnace. A clean, scale-free surface is critical for good surface quality. The pipe shell is further reduced to specified dimensions by the stretch mill. The pipes then are conveyed to the cutoff mechanism, where they are cut to the prescribed length.Then these pipes are bundled and directed to subsequent finishing and inspection operations before shipment.

- This process is used to make smaller sizes of seamless pipe, typically 1 to 6 inches (25 to 150 mm) diameter

- The ingot of steel is heated to 2,370 °F (1,300 °C) and pierced.

- A mandrel is inserted into the tube and the assembly is passed through a rolling (mandrel) mill.

- Unlike the plug mill, the mandrel mill reduces wall thickness continuously with a series of pairs of curved rollers set at 90° angles to each other.

- After reheating, the pipe is passed through a multi -stand stretch-reducing mill to reduce the diameter to the finished diameter.

- The pipe is then cut to length before heat treatment, final straightening, inspection, and hydrostatic testing.

API 5L PSL1 Grade B seamless steel pipes

Mannesmann plug mill process of seamless steel pipes:

There are some similarities between mannesmann plug mill process and mandrel mill process, the main difference is that the mandrel mill is replaced by rolling plug mill.

In mannesmann plug mill process, a solid round billet is used. The round billet is first heated uniformly in the rotary hearth heating furnace and then pierced. The round billets are pierced by a cross roll piercer. The piercing mill presses the billet against the plug to perforate it and then rolls the billet between the roll and the plug. The pierced billet or hollow tube is then roll reduced (hot or cold) to obtain the specified outside diameter and wall thickness.This method has a high production speed, but has high requirements on the processability of the tube blank, and is mainly suitable for the production of carbon steel and low alloy steel tubes.

- This process is used to make larger sizes of seamless pipe, typically 6 to 16 inches (150 to 400 mm) diameter.

- An ingot of steel weighing up to two tons is heated to 2,370 °F (1,300 °C) and pierced.

- The hole in the hollow shell is enlarged on a rotary elongator, resulting in a short thick-walled tube known as a bloom.

- An internal plug approximately the same diameter as the finished diameter of the pipe is then forced through the bloom.

- The bloom containing the plug is then passed between the rolls of the plug mill.

- Rotation of the rolls reduces the wall thickness.

- The tube is rotated through 90° for each pass through the plug mill to ensure roundness.

- The tube is then passed through a reeling mill and reducing mill to even out the wall thickness and produce the finished dimensions.

- The tube is then cut to length before heat treatment, final straightening, inspection, and hydrostatic testing.

Extrusion process of seamless steel pipes:

The extrusion method uses a piercing machine to perforate a tube blank or a steel ingot, and then extrudes it into a steel tube by an extruder. This method is less efficient than the cross-rolling method and is suitable for producing a high-strength alloy steel tube.

We can supply seamless steel pipes made by various manufacturing methods,if you want to know more about seamless steel pipes or other pipeline products,please contact us: sales@haihaogroup.com