How to distinguish inferior steel pipe?

Steel pipe is a kind of common construction material in our daily life such as welded steel pipe. Therefore, manufacturers who expertise in steel pipe production are various. In these factories, their production ability is different, so the steel pipe quality is also quite uneven. Some shoddy manufacturers who produce poor quality steel pipe will mislead the decision of customers, which is shameful but can not be avoided. Then, how to distinguish the quality of steel tube and square tube? How to choose suitable products with reasonable price? We should learn some basic knowledge about these question.

S31803 seamless pipe for the Navy Wharf Upgrade

- The folding is easy to happen with inferior steel tube

- Folding is formed on the surface of the pipe line, this kind of defect often throughout the entire product longitudinal. The reason for causing of fold is due to the pursuit of high efficiency, large reduction of the inferior manufacturer, when go on the next rolling, the folding happens, and the folding products will be cracking after bending, and the strength of steel will decreased.

- The inferior steel tube has pitted surface

- Pits is due to the defects of the irregular uneven steel surface caused by the worn groove. Because of the pursuit of profit, the inferior steel pipe manufacturer often appear the overweight groove rolling.

- The inferior steel tube surface are prone to scarring

- For two reasons: (1) the inferior steel pipe material uneven with impurities. (2). The inferior material manufacturer with simple equipment which is easy to stick steel, these impurities after the roll bite are prone to scarring.

- The surface of the inferior material is easy to have crack for the reason that it’s blank is adobe, and in the process of cooling due to the effect of thermal stress, cracks, after rolling, there is crack.

- The inferior steel pipe is easy to scratch for the reason that the inferior steel pipe factory has simple equipment which is easy to produce burr and scratch steel surfaces. The deep scratches will reduce the strength of the steel.

- The inferior steel tube has no metallic luster, it is reddish or similar to the color of the pig iron for its original material is adobe. And the characteristics of steel pipe cannot reach the required standard.

- The transverse bar of the inferior steel pipe is thin and low, and often appear phenomenon of discontent, because the manufacturers want to achieve big minus tolerance, finished product quality is not in accordance with the standard.

- The cross-section of the inferior steel tube is oval, because the factory in order to save material, the quantity of the finished product roll is big, the strength of rebar is greatly decreased, but also do not conform to the standard of rebar shape size.

- The high quality steel composition is uniform, the cold shearing machine has high tonnage, and the cutting head end is smooth and neat, and the material of the inferior manufacturer is poor, cutting head end is not smooth or uneven, and also has no metallic luster.

- The impurities of the inferior steel pipe is very large, but the steel density is small, and the size out-of-tolerance is serious, so in the absence of vernier caliper, can be checked to weigh it.

- The inner diameter of the inferior steel pipe is volatile, the reason is: 1. the steel temperature is unstable; 2. the composition of steel is not uniform; 3. Because of the poorly equipped, and low foundation strength, there will be a larger changes within the same week, the steel bar caused by uneven on fracture.

- The high quality tube logo and printing are specification.

- The steel pipe diameter more than 16, the spacing between the two trademark all over IM.

- The inferior steel rebar longitudinal reinforcement often undulate.

- The inferior steel pipe manufacturer with no traffic, so the packing is loose.

The pipe component distribution is very uniform for high quality steel pipe and its surface is smooth and neat such as cold rolled steel pipe. However, the steel pipe whose quality is inferior has obvious folding mark on the surface, which can form a variety of folding line. The folding mark will affect the strength of steel pipe seriously; it will become a potential safety issue afterwards. For inferior steel tube, there are a lot of impurities in component, resulting in impure raw materials, which can cause uneven material easily. This kind of poor quality steel pipe can not be applied in actual construction project.

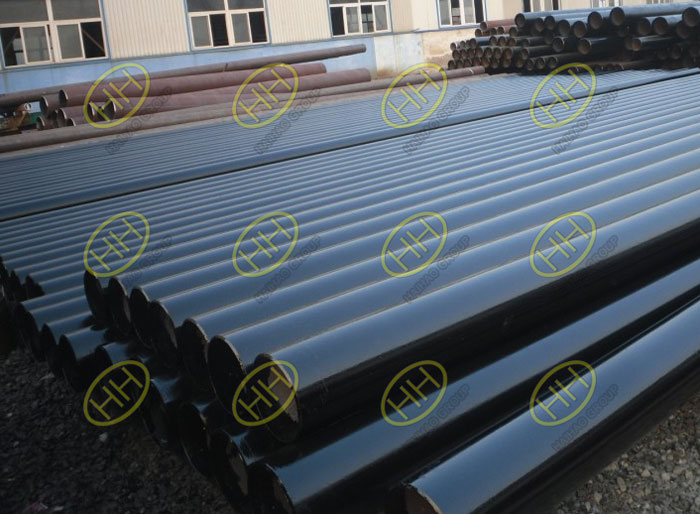

Carbon steel hot rolled steel pipes finished in Haihao Group

Good quality steel pipe such as hot dipped galvanized steel pipe has lots of excellent performances. For example, premium quality steel pipe has very high strength which can not be scratched easily and light scratching is not obvious. However, inferior steel pipe produced by a set of simple equipment will easily has burr that will lower steel pipe strength. Steel pipe with metallic luster ranks high class in steel pipe market, but inferior steel pipe more or less has rugged dot which is caused by simple and crude production equipment. We should choose the steel pipe with smooth surface without obvious burr.

The above basic points, generally can be used to judge the quality of steel pipe. For all the steel pipe manufacturers, each manufacturer has their own steel pipe price in terms of their types or specifications. In the fluctuate steel pipe market, choosing desirable products with good value is not an easy job. It is a time as well as energy commitment. Besides, we need to mater some related information in advance. Therefore, learning some judgment method of selecting is very important. If you have other questions about the select approaches, hope you can leave your messages below.

If you want to have more information about the article or you want to share your opinion with us, contact us at sales@haihaogroup.com