Manufacturing method of marine seamless steel pipe

Marine seamless steel pipes can be divided into hot-rolled pipes,cold-rolled pipes,cold-drawn pipes and extruded pipes according to different production methods.(Seamless steel pipes manufacturing process)

1. Hot-rolled stainless steel seamless pipes are generally produced on automatic tube rolling mills. The solid billet is checked and cleared of surface defects, cut into the required length, centered on the end face of the billet perforation, then sent to the heating furnace for heating, and perforated on the perforator. Under the action of the roll and the top, a cavity is gradually formed inside the billet, which is called capillary. It is then sent to the automatic pipe mill to continue rolling. Finally, the wall thickness of the whole machine is equalized, and the sizing machine is used to calibrate the diameter, which meets the specifications. It is an advanced method to produce hot-rolled seamless steel tube by continuous pipe rolling mill.

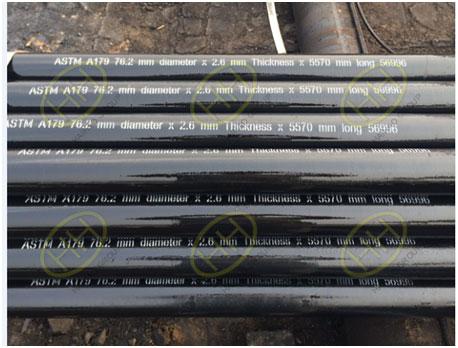

ASTM A179 seamless carbon pipe

2. If we want to obtain seamless pipes with smaller size and better quality, we must adopt cold rolling, cold drawing or combination of the two methods. Cold rolling is usually carried out on a two-roll mill. Steel pipes are rolled in an annular pass consisting of a circular groove with variable cross-section and a fixed conical head. Cold drawing is usually carried out on single-chain or double-chain cold-drawing machines of 0.5-100T.

3. The extrusion method is to place the heated tube blank in a closed extrusion cylinder, and the perforating rod moves with the extrusion rod to extrude the extruded part from a smaller die hole. This method can produce steel pipes with smaller diameter.

Our company can produce seamless steel pipe of various sizes and types. If you would like to know more about pipe fitting products, please contact us.Email:sales@haihaogroup.com