-

Endeavour for 40 years, passion for the future. In 1982, Hebei Haihao Group officially established its factory in Mengcun County, the hometown of pipe fittings in China. From a few people to more than 700 people, Haihao has always put product quality and s ...

-

Today, a batch of steel pipes ordered by Dutch customers have been inspected and ready for packaging and shipment. The customer signed a supply contract with Haihao last year, ordering products including flanges, elbows, and steel pipes. The flanges and el ...

-

Seamless steel pipe is a steel pipe perforated by a whole round steel, with no weld on the surface. It can be divided into general purpose (used for water and gas pipelines and structural parts, mechanical parts) and special purpose (used for boilers, geol ...

-

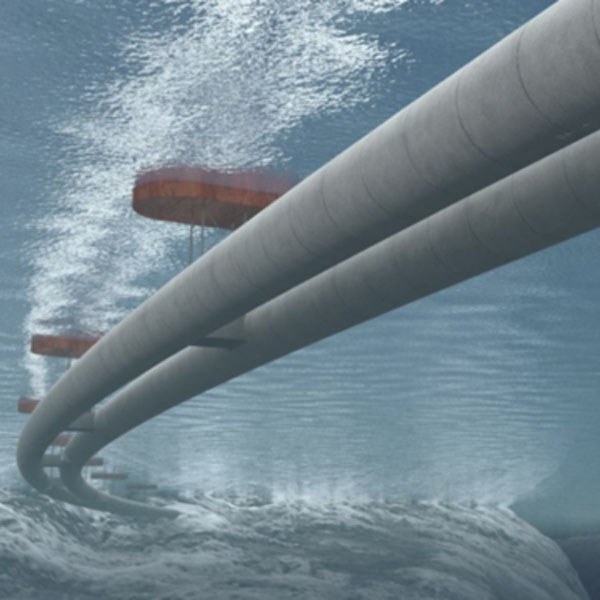

There is a big difference between submarine pipelines and land pipelines. In addition to the working loads borne by the pipelines during normal operation, the submarine pipelines also need to consider the tensile buckling stress and residual stress after t ...

-

The pipeline varies according to the transportation medium,and the requirements for some parameters are different. Only by understanding their differences can we produce pipes with different parameters according to different needs. Now let’s take a l ...

-

The year 2023 is approaching us with vigor and vitality. In the New Year, Haihao Group will stay true to its original intention and forge ahead, working hand in hand with you to create a better world. Haihao Group

-

Qatar is an important member of the the Belt and Road, and the local oil and gas resources are very rich. Driven by the the Belt and Road policy, the products of Haihao Group have been more and more applied in local projects in Qatar. On Monday, the produc ...

-

As we said before, there may be some situations in pipeline engineering where hydrostatic test cannot be carried out. As an enterprise specializing in R&D, production and sales of pipeline engineering supporting products, Haihao Group has professional ...

-

Not long ago, the prefabricated parts ordered by Chilean customers completed the hydrostatic test before delivery. Hydrostatic testing is a commonly used testing method to check the strength and air tightness of pipelines, which is widely used in pipeline ...

-

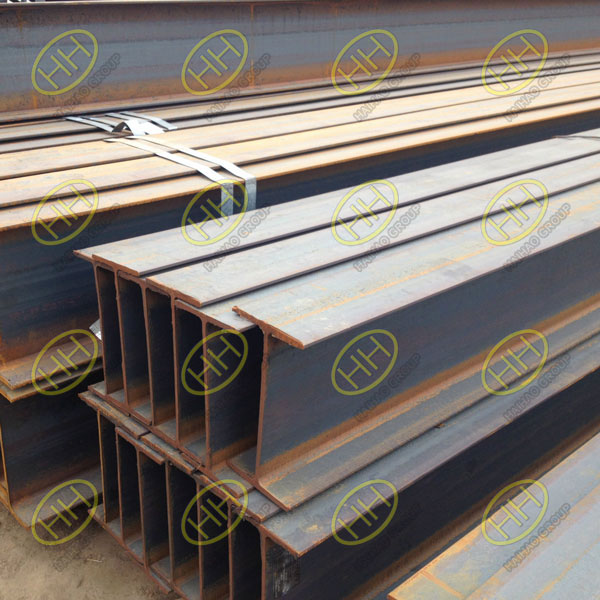

H Beam is a kind of economical and efficient section steel with more optimized section area distribution and more reasonable strength weight ratio. It is named because its section is the same as the “H”. Since all parts of H-shaped steel are ar ...

-

In recent years, clean energy represented by natural gas is developing rapidly in the world. The East Africa region has attracted the attention of the international energy market due to its rich natural gas resources. In particular, the offshore area in th ...

-

A182 F53 is a ferritic-austenitic duplex stainless steel that combines the beneficial properties of both. Due to the high content of chromium and molybdenum in this steel, it has good resistance to pitting corrosion, crevice corrosion and uniform corrosion ...

-

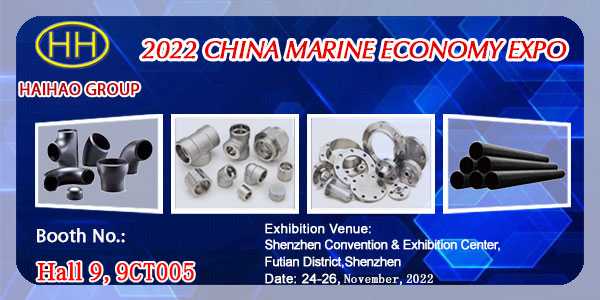

Today, the 2022 China Marine Economy Expo, the 2022 Shenzhen International Ocean Week and the 2022 Shenzhen Ocean Industry Investment Promotion Conference opened in Shenzhen. Haihao Group 9CT005 booth The Expo covers an exhibition area of 60000 square mete ...

-

Haihao Group will take many important products to participate in the 2022 China Marine Economy Expo held in Shenzhen Convention and Exhibition Center (Futian District) on November 24-26, 2022, to help China achieve the upgrading and development of pipeline ...

-

The United Arab Emirates is a member of the Organization of Petroleum Exporting Countries (OPEC), and its national economy is dominated by petroleum production and petrochemical industry. With the promotion of the the Belt and Road policy, trade between th ...

-

2022 SSNAME Academic Conference The 2022 SSNAME academic conference was successfully held on November 12. The theme of the conference was “Innovation drives high-quality development of offshore engineering”, Haihao Group was honored to be invit ...

-

Wang Shoujun, president of the Chinese Nuclear Society, introduced at the 23rd Pacific Nuclear Energy Conference held on the 1st that as of June 2022, China had 53 nuclear power generating units in operation, 23 nuclear power generating units under constru ...

-

China Marine Economy Expo, the only national marine economy exhibition in China, is an important window to show the achievements of China’s marine economy development. With the theme of “enabling scientific innovation and sharing deep blue̶ ...

-

At the beginning of this year, British customers signed an order contract with Haihao. Customers want to order flanges, steel pipes, elbows and other piping products in Haihao. By the middle of October, the flanges and steel pipes had been supplied. On Oct ...

-

At the beginning of this year, a customer in Indonesia signed an order contract for a batch of steel pipes with Haihao Group, and the customer wanted to customize a batch of seamless steel pipes. According to the progress of the project, the goods need to ...