-

Different types of flange faces are used as the contact surfaces to seat the sealing gasket material. ASME B16.5 and B16.47 define various types of flange facings, including the raised face, the large male and female facings which have identical dimensions ...

-

Polishing refers to the use of mechanical, chemical or electro chemical action to reduce the surface roughness of the fitting, in order to obtain a bright, flat surface processing method. It uses polishing tools and abrasive particles or other polishing me ...

-

At present, polishing is widely used in the surface modification of pipe fittings, flanges, steel pipes and other pipeline products. There are six main polishing methods: mechanical polishing, chemical polishing, electrolytic polishing, ultrasonic polishin ...

-

Polyurethane coating is a kind of anticorrosive coating, its main components are isocyanate-NCO and hydroxyl. At present, it is widely used in pipe fittings, pipes, flanges and other pipeline products surface anti-corrosion. As a surface anticorrosive coat ...

-

In some cases, butt weld fittings can be externally coated with protective materials, internally lined (example PTFE may be inserted to enhance the resistance of the bare metal to corrosive fluids) or clad. PTFE Lined Pipe Fittings Advantages of Lined Pipe ...

-

ASTM A216 covers three grades of carbon steel (Grades WCA, WCB, and WCC). The selection of which grades shall depend on the design and service conditions, mechanical properties, and the high temperature characteristics. Steel castings shall be heat treated ...

-

Generally speaking, the mechanical properties of castings are lower than those of forgings of the same material. In addition, forging process can ensure the continuity of metal fiber structure, keep the fiber structure of forgings consistent with the shape ...

-

Hebei Haihao Group specializes in the production of elbow, tee, flange, and other pipe fittings commonly used in water supply pipeline system. As a water supply pipe, it is required that the pipe fittings and flange materials are hygienic, safe, energy-sav ...

-

The stainless steel pipe fitting has the characteristics of easy installation, high performance and durability, and is widely used in the construction and installation of various pipelines. In recent years, stainless steel pipe fitting products have been u ...

-

Duplex stainless steels are called “duplex” because they have a two-phase microstructure consisting of grains of ferritic and austenitic stainless steel.When duplex stainless steel is melted it solidifies from the liquid phase to a completely f ...

-

Duplex stainless steel is a kind of stainless steel with dual phase microstructure of ferrite and austenite. The proportion of ferrite and austenite in solution structure is about 50%, and the content of less phase is more than 30%. The metallographic stru ...

-

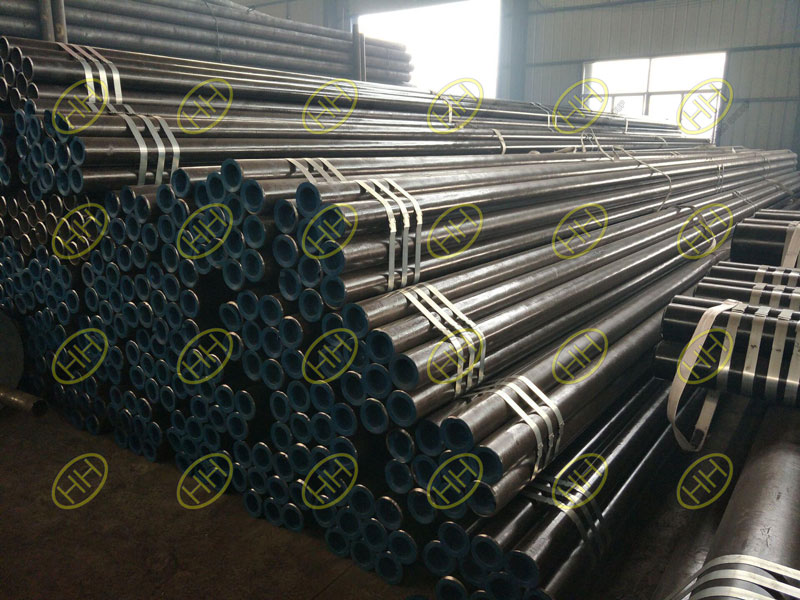

Hebei Haihao Group specialized in flange and pipe fittings. Carbon steel pipe fittings is an environmentally friendly material. Compared with welding operations and threading operations, carbon steel pipe fittings-site installation is very convenient. Low ...

-

Pressure (psig) and temperature (deg F) ratings for A-53 B and A-106 B, A333, A334 and API 5L carbon steel pipes – temperatures ranging 100 °F – 700 °F Ratings calculated (see below the table) according ASME B31.3-2002 Table K-1 for plain end s ...

-

316Ti stainless steel has traditionally been designated by German engineers and users, the original steel grade of the UK is 320S31, which is basically a standard carbon 316 stainless steel with titanium stability. At the temperature range of 425 – 8 ...

-

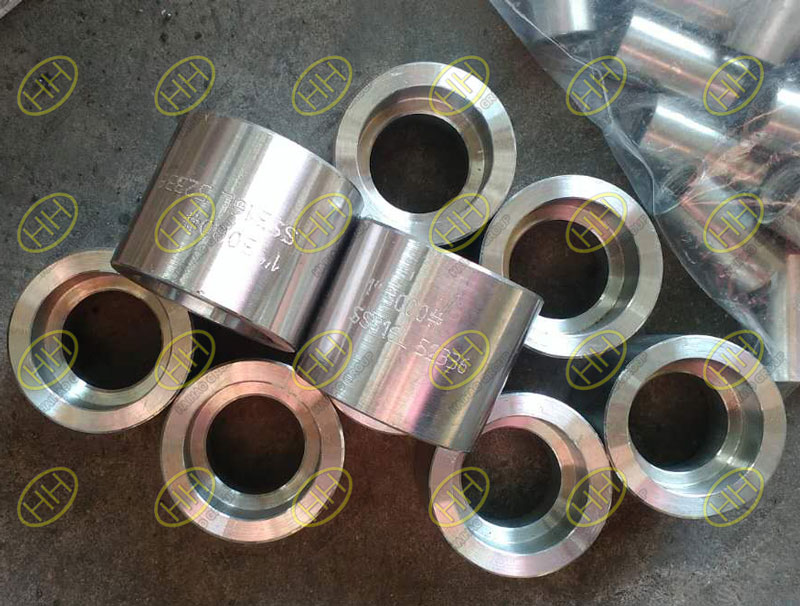

Cast flanges can be manufactured in various kinds of complex shapes which are difficult to be obtained for the flanges which are produced by other manufacturing methods. Cast flanges have very low costs, which make them much cheaper than forged flanges. T ...

-

Bolts, screws and studs are used extensively in the manufacturing industry. Although similar in appearance, however, each item has its own unique purpose and characteristics. To learn more about the nuances between bolts, screws and studs — and which one i ...

-

Magnetic particle detection is applicable to the following range: 1.It is suitable for the detection of surface and near-surface defects of ferromagnetic materials, such as cracks with extremely narrow gap between surface and near-surface and other defects ...

-

Magnetic particle detection is a method of observing defects by using magnetic particle as display medium. According to the type of magnetic powder medium applied during magnetization, the detection methods are divided into wet method and dry method. Accor ...

-

With the deepening and development of the reform and opening up, China’s magnetic particle detection technology has developed rapidly, and the standardization work has made important progress. With the development of digital technology, magnetic powd ...

-

Radiographic methods commonly used in the industry are X-ray inspection and gamma ray inspection. Refers to the use of electromagnetic waves to detect metal workpieces, similar to X-ray. The passage of the ray through the material to the backsheet will res ...